Natural Stacking Density Meter

499.00 - 999.00 USD ($)

Product Details:

- Display Type Digital LCD

- Operating Voltage 220V AC

- Application Measurement of powder stacking density (untapped)

- Number of Specimens 1 at a time

- Power Supply 220V AC 10%, 50Hz

- Measuring Range 0.01 2.0 g/cm

- Accuracy 0.01 g/cm

- Click to view more

X

Natural Stacking Density Meter Price And Quantity

- 499.00 - 999.00 USD ($)

- 1 Set

Natural Stacking Density Meter Product Specifications

- Compact, lightweight, easy to clean

- Standard (customizable on request)

- 60 mm

- 250 mm

- 5% 85% RH, non condensing

- Instant read

- Basic, No external interface

- 0.01 g

- 0.01 2.0 g/cm

- Manual operation

- Approx. 20 kg

- Up to 200 mm

- Bench-top

- Manual

- Standard

- Natural Stacking Density Meter

- 10C 50C

- 50Hz

- 100 mm

- 0.01 g/cm

- 0.01 2.0 g/cm

- 220V AC 10%, 50Hz

- Up to 500 g

- Laboratory/Industrial

- 1 at a time

- Measurement of powder stacking density (untapped)

- 220V AC

- Digital LCD

Natural Stacking Density Meter Trade Information

- shenzhen or guangzhou

- 300 Set Per Month

- 7 Days

- All India

Product Description

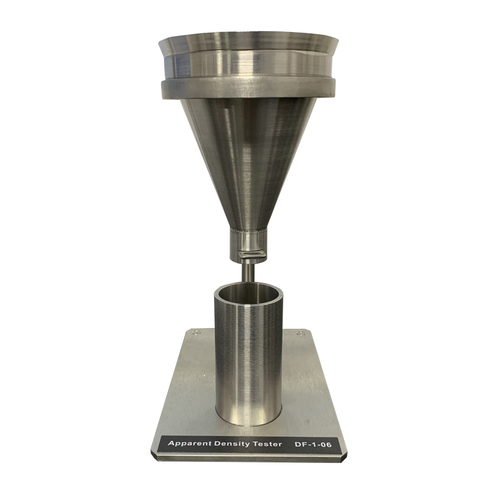

Natural Stacking Density Meter

1.Introduction

DF-1-03 is designed and produced based on GB/T 16913.3-1997.it is application to measuring bulk density of powder.

2.Principle

The powder drop from high place freely and fill with measuring cylinder; By measuring the gram mass and volume in the status of loose. can get bulk density.

3.Structure

(1)Funnel(diameter of outflux 12.7mm)

(2)Obstructed rod

Stainless steel(304),to prevent the dust drop when placed into funnel

(3)Measuring cylinder

100ml stainless steel(304) measuring cylinder.inner diameter 39mm

(4)Flow distance

(5)Scraper blade

Stainless steel(304),to remove the extra dust when it is droped into funnel

Precision Lab Solution for Powder Analysis

The Natural Stacking Density Meter excels in providing accurate, repeatable measurements of powder stacking density, vital for quality assurance in pharmaceuticals, chemicals, and materials testing. Its durable stainless steel and acrylic build ensure long-lasting operation and ease of cleaning. This benchtop unit offers convenient manual control and quick results on its digital LCD, efficiently serving both laboratory and industrial workflows.

Designed for Durability and Convenience

Made with top-grade stainless steel and acrylic, this density meter resists corrosion and withstands frequent use. The stable, vibration-free installation ensures precision, while the compact footprint makes it simple to place on any workbench. Easy disassembly and cleaning reduce downtime between tests, supporting efficient sample throughput.

FAQs of Natural Stacking Density Meter:

Q: How should the Natural Stacking Density Meter be installed for optimal performance?

A: To ensure accurate measurements, the meter must be placed on a stable, vibration-free surface in a laboratory or industrial environment. This reduces external influences that could affect the stacking density results.Q: What materials can be tested using this density meter?

A: The device is designed for measuring untapped stacking density of powders, making it suitable for a variety of powdered substances used in pharmaceutical, chemical, and material science applications.Q: When is it necessary to calibrate the device?

A: Calibration should be performed at regular intervals or when the meter is relocated to a new environment, following IS, ASTM, and ISO standards to maintain consistent accuracy.Q: Where are the major applications for this equipment?

A: Its commonly used in laboratory research, quality control departments, and manufacturing processes that require precise measurement of powder bulk properties.Q: What is the sample handling process for testing?

A: Place the powder in the provided stainless steel collection cup, insert the sample into the test chamber using the 60 mm funnel, and operate the unit manually. The measurement is displayed instantly on the digital LCD.Q: How does using this meter benefit laboratory operations?

A: With its instant digital readings, high accuracy, and simple cleaning process, the meter streamlines quality checks, reduces operator error, and boosts productivity during powder analysis.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email