Simulated Sunlight Environmental Xenon Test Machine

Product Details:

- Measuring Range Light intensity up to 1200 W/m

- Humidity 10%~98% RH adjustable

- Power Supply AC 220V, 50/60Hz

- Number of Specimens Up to 32

- Temperature RT+10C~80C adjustable

- Response Time Instant

- Mounting Type Floor standing

- Click to view more

Simulated Sunlight Environmental Xenon Test Machine Price And Quantity

- 1 Set

- 2999.00 - 6899.00 USD ($)/Set

- Over-temperature and over-current protection

- Rotating drum or flat rack selectable

- Stainless steel chamber

- ASTM G155, ISO 4892-2, GB/T 16422.2

- ±5%

- 0~9999 hours

- Air cooling / Water cooling (depends on configuration)

- Viewing window with safety lock

- 2.5 kW

- Max 4.5 kW

- Air-cooled xenon arc lamp

- PLC with programmable logic

- 1200×760×1700 mm

- 5°C~35°C

Simulated Sunlight Environmental Xenon Test Machine Product Specifications

- 400 mm

- Up to 32

- RT+10C~80C adjustable

- Instant

- Varies by configuration

- Floor standing

- Light intensity up to 1200 W/m

- Adjustable

- Programmable, Touch Screen

- 10%~98% RH adjustable

- AC 220V, 50/60Hz

- Approx. 260 kg

- Simulated Sunlight 300~4000nm

- UV and light aging test

- Color touch screen LCD

- 50/60 Hz

- 1% for irradiance

- Standard panel or customized

- Automatic

- Programmable cycles, safety protection, rapid cooling

- 0.1 W/m

- 1700 mm

- 200 mm

- Material weathering, aging, and durability test

- 220V AC

- USB, RS232

- 0.5~0.8 MPa (if air cooling present)

- Standard

- Xenon Test Machine

- Over-temperature and over-current protection

- Rotating drum or flat rack selectable

- Stainless steel chamber

- ASTM G155, ISO 4892-2, GB/T 16422.2

- ±5%

- 0~9999 hours

- Air cooling / Water cooling (depends on configuration)

- Viewing window with safety lock

- 2.5 kW

- Max 4.5 kW

- Air-cooled xenon arc lamp

- PLC with programmable logic

- 1200×760×1700 mm

- 5°C~35°C

Simulated Sunlight Environmental Xenon Test Machine Trade Information

- Shenzhen

- 300 Set Per Month

- 7 Days

- All India

Product Description

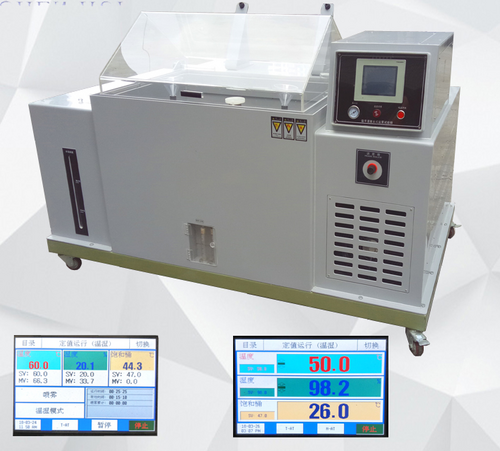

Simulated Sunlight Environmental Xenon Test Machine

Application:

By using the xenon lamp to simulate sunlight,and condensation of moisture to simulate rain and dew.put the testing specimen under sunlight at some temperature and humidity alternant cycle program to do the testing.the machine can help to show the bad effect on specimen from outdoor environment in short time with several days or weeks instead of years.The testing data can help to choose more suitable materials.and improve existed materials.and evaluate the changing of formula how to effect the durability of products.

Features:

1.Adopt the long axis fan motor,anti high and low temperature stainless steel multi-blades wheel,have good convection.and vertical diffusion cycle.

2.Double-layer anti-high temperature sealing strip has been used between the door and the box.to make sure the leakproofness for the testing area.

3.Adopt non-counteractive door knob,more easy operation.

4.Adopt high quality fixable PU running wheel of the bottom of machine.

5.Adopt multi-layer hollow tempered glass inspection window.(can observe the testing procedure clearly)

6.Irregular shape sample holder,make the installation of testing specimen more easier.and convenient to be used.

7.The working life of xenon lamp is determined by the radiation level.normal service life of lamp is 1600 hours.Lamp is easy to be changed.The effective filter can make sure spectrum demanded can be offered.

Specification:

Model: DH-XD-150

Inner size: WHD(cm)50*60*50

External size: WHD(cm)105*185*115

Temperature range0-80 degree, adjustable

Humidity range:30%-98%R.H

Type of light source imported air-cooled full solar spectrum long arc xenon lamp (average service life is around 1600 hours)

Rainfall time: 1-9999min, adjustable

Rainfall cycle: 1-240min,interval is adjustable

Wavelength: 290nm-800nm

Advanced Xenon Arc Technology

Harnessing a 2.5 kW air-cooled xenon arc lamp, this test machine simulates natural sunlight with exceptional accuracy and irradiance uniformity (5%). It is designed to replicate diverse sunlight conditions, enabling comprehensive material assessments within laboratory settings.

Versatile and Reliable Testing Environment

Built with a stainless steel chamber and a viewing window with safety lock, the unit allows safe and visible ongoing tests. Highly customizable, it features adjustable temperature (RT+10C~80C), humidity (10%~98% RH), test stroke (200 mm), and a programmable touch screen PLC for easy operation.

Wide Application and Compliance

Compliant with ASTM G155, ISO 4892-2, and GB/T 16422.2, the xenon test machine serves industries requiring rigorous weathering, aging, and UV resistance testing for coatings, plastics, textiles, and more. Automated performance ensures high throughput and trustable results.

FAQ's of Simulated Sunlight Environmental Xenon Test Machine:

Q: How does the Simulated Sunlight Xenon Test Machine operate?

A: The machine uses a high-powered xenon arc lamp to replicate sunlight in a controlled chamber. Test parameters like irradiance, temperature, humidity, and test cycles are programmed via the PLC touch screen, making the automation process seamless and precise.Q: What materials can be tested with this xenon arc system?

A: It is suitable for a variety of materials including plastics, coatings, textiles, paints, automotive components, and other samples needing accelerated weathering or light aging evaluations. It accommodates up to 32 specimens with standard or customized sizes.Q: When should I choose air cooling versus water cooling for the machine?

A: Air cooling is normally sufficient for standard operations, ensuring efficient lamp and chamber cooling. Water cooling may be selected for intensive tests or high-load environments to maintain optimum temperature and enhance system longevity.Q: Where can this equipment be installed and used?

A: Designed as a floor-standing unit with dimensions of 12007601700 mm, it can be installed in laboratories, quality control departments, or production facilities. Ensure the ambient temperature is between 5C~35C and the power supply is 220V AC.Q: What is the process for conducting a test with this machine?

A: Samples are placed on a rotating drum or flat rack. After setting test parameters on the touch screen, the chamber simulates sunlight and environmental conditions. The automated system monitors cycles, and data is logged for analysis through USB or RS232 interface.Q: How is the safety of users and samples ensured during operation?

A: The test machine features over-temperature and over-current protection, a viewing window with a safety lock, and rapid cooling options. These systems protect both personnel and specimens throughout the test process.Q: What benefits does this xenon test machine offer to manufacturers and researchers?

A: It delivers standardized, repeatable, and quick results that help predict long-term material durability. Automation, programmable cycles, and compliance with global standards improve laboratory efficiency and support reliable product development.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+