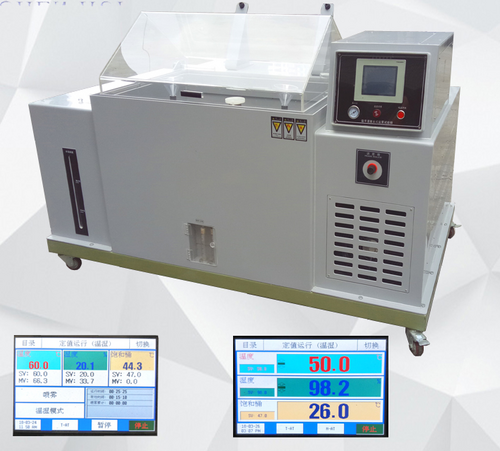

Salt Spray Corrosion Resistance Environmental Testing Chamber

Product Details:

- Features Automatic water replenishment, programmable timer, over-temperature protection

- Specimen Size Max 150 mm x 70 mm

- Humidity 85%~95% RH

- Automation Grade Semi-Automatic

- Gas Pressure 0.8 - 2.0 bar

- Equipment Type Salt Spray Corrosion Resistance Environmental Testing Chamber

- Power Supply 220V AC, 50Hz

- Click to view more

Salt Spray Corrosion Resistance Environmental Testing Chamber Price And Quantity

- 399.00 - 1999.00 USD ($)

- 1 Set

- FRP (Fiber Reinforced Plastic)

- Continuous or intermittent

- Specimen holder, air compressor (optional)

- 0°C~35°C, non-condensing

- Precision glass nozzle

- 5% NaCl standard

- Over-temperature and low-water level alarm

- Integrated with manual valve

- 2 pcs, 80cm² each

- Transparent Acrylic with sealing gasket

Salt Spray Corrosion Resistance Environmental Testing Chamber Product Specifications

- Adjustable

- Industrial / Laboratory

- 85%~95% RH

- Digital PID Control

- Automatic water replenishment, programmable timer, over-temperature protection

- Max 150 mm x 70 mm

- Continuous or cyclic

- 400 mm

- Salt Spray Corrosion Resistance Environmental Testing Chamber

- 220V AC, 50Hz

- 0-350 hours (programmable)

- Corrosion Resistance Testing

- RS232

- 0.1C

- Digital LCD Display

- Semi-Automatic

- 0.8 - 2.0 bar

- 220V

- 0.1C

- < 3 sec

- Approx. 80 kg

- Up to 15 samples

- 120 litres

- 35C 1C (Test Chamber), 47C 1C (Saturator)

- 600 mm

- 50 Hz

- 1/4 inch

- 1200 mm

- Floor standing

- FRP (Fiber Reinforced Plastic)

- Continuous or intermittent

- Specimen holder, air compressor (optional)

- 0°C~35°C, non-condensing

- Precision glass nozzle

- 5% NaCl standard

- Over-temperature and low-water level alarm

- Integrated with manual valve

- 2 pcs, 80cm² each

- Transparent Acrylic with sealing gasket

Salt Spray Corrosion Resistance Environmental Testing Chamber Trade Information

- shenzhen

- 300 Set Per Month

- 7 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

This product meets the standards of CNS, ASTM, JIS, ISO, etc.The salt spray test is to test the corrosion resistance of the surface of various materials after coating, electroplating, anodizing, anti-rust oil and other anti-corrosion treatment.

Standards:

CNS3627,3885,4159,7669,8886,JISD-0201,H-8502,H-8610,K-5400,Z-2371,ISO 3768,3769,3770,ASTMB-117,B-268,GB-T2423,GJB 150

Material:

- The cover is made up of 5MM imported transparent (Germany YLIS) acrylic board. Fine workmanship, beautiful appearance, high transparency.

Specification:

Model: DHL-60

Volume:108L

Interior dimensions(mm)L*W*H: 600*450*400

Exterior dimensions(mm)L*W*H:1060*580*1050

Sealing method: The inside and outside box is connected to the sealing groove, using water sealing. avoid salt spray leakage.

Temperature range:

1: Laboratory temperature: 35-50 degree(can be set arbitrarily)

2: Pressure bucket temperature:47-63 degree(can be set arbitrarily)

Power: AC220V 50HZ 15A

Advanced Corrosion Testing Capability

This chamber offers a programmable test range of up to 350 hours, supporting both continuous and cyclic testing modes. It maintains precise chamber conditions at 35C 1C and humidity at 85%~95% RH, simulating harsh environments for comprehensive sample evaluation. The digital LCD display ensures clear parameter monitoring throughout testing cycles.

Efficient Sample Handling and User Safety

Equipped with a transparent acrylic door and sealing gasket, specimen holders, and collector funnels for accurate measurement, the chambers semi-automatic control and integrated safety featuressuch as over-temperature and low-water level alarmspromote both ease of use and operational safety. The automated water replenishment further streamlines test processes.

Designed for Versatility and Reliability

Ideal for various industriesfrom manufacturing to research laboratoriesthis testing chamber accommodates up to 15 specimens and operates in ambient environments from 0C to 35C. Its floor-standing design, RS232 interface, and digital PID control offer versatility, programmable customization, and reliable data output for performance assessment.

FAQs of Salt Spray Corrosion Resistance Environmental Testing Chamber:

Q: How does the Salt Spray Corrosion Resistance Chamber operate for corrosion testing?

A: The chamber utilizes a programmable digital PID control system to maintain temperatures at 35C 1C (test chamber) and 47C 1C (saturator) while delivering salt spray via precision glass nozzles. You can select continuous or intermittent (cyclic) spray modes to suit your corrosion analysis requirements.Q: What types of specimens and how many can be tested simultaneously?

A: The chamber accommodates up to 15 samples at once, with each specimen measuring a maximum of 150 mm by 70 mm. Adjustable specimen holders are provided for secure placement and optimal exposure to the salt spray environment.Q: When should the chambers safety features activate, and what protections are in place?

A: Safety features such as over-temperature and low-water level alarms are triggered if preset temperature thresholds are breached or water levels fall below safe limits. These mechanisms prevent equipment damage and ensure the safety of operators during testing.Q: Where is this testing chamber ideally used, and by whom?

A: Commonly used in industrial and laboratory environments, the chamber is suitable for manufacturers, exporters, suppliers, and research institutions that require rigorous corrosion resistance testing of materials, coatings, or components.Q: What is the process for preparing a test and monitoring results?

A: To begin testing, place specimens on the holder, set desired parameters via the digital controller, and initiate the test. The system automatically maintains temperature, humidity, and spray concentration while results can be monitored in real-time through the digital LCD display. The programmable timer ensures precise test duration control.Q: How does the automatic water replenishment feature benefit users?

A: Automatic water replenishment ensures that the chamber maintains optimal water levels throughout extended testing periods, minimizing manual intervention, reducing the risk of interruptions, and supporting consistent test conditions.Q: What are the main benefits of using this Salt Spray Corrosion Resistance Chamber?

A: Key benefits include high testing accuracy (0.1C), programmable operation up to 350 hours, fast response time (<3 sec), comprehensive safety features, and a user-friendly interface, making it a reliable choice for corrosion resistance validation across various industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+