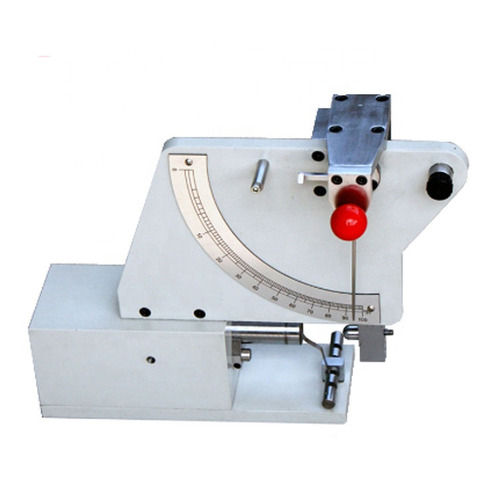

Torque Measuring Machine Torque Testing Equipment for Bottle Cap

Product Details:

- Application Testing opening and closing torque of bottle caps

- Max Height 300 mm specimen

- Features Peak hold, data output, programmable limit

- Accuracy 1% of reading

- Measuring Range 0 to 10 Nm

- Test Range 0-10 Nm

- Mounting Type Bench-top

- Click to view more

Torque Measuring Machine Torque Testing Equipment for Bottle Cap Price And Quantity

- 479.00 - 1199.00 USD ($)

- 1 Set

- Compliant with CE requirements

- 420 mm x 300 mm x 240 mm

- Stores up to 500 test results

- High-strength aluminum alloy

- < 30 W

- 10 - 150 mm diameter

- USB & RS232 ports

- Provided with traceable calibration certificate

- Automated electronic overload alarm

- Nm, kgf-cm, lbf-in selectable units

- Adjustable rubber grip jaws

Torque Measuring Machine Torque Testing Equipment for Bottle Cap Product Specifications

- Cap torque testing for bottles, jars, containers

- <1 sec

- Torque Measuring Machine

- 50 Hz

- 10C-40C operating

- 1 at a time

- AC 220V, 50Hz

- Frame body hardened >HRC 45

- Standard bottle fixture

- 0.01 Nm

- RS232

- 10-150 mm diameter bottle cap

- 100 mm

- 10 Nm

- 10-100 RPM adjustable

- 85% RH

- Bench-top

- 0-10 Nm

- Peak hold, data output, programmable limit

- 1% of reading

- 0 to 10 Nm

- 300 mm specimen

- 0-150 mm

- Testing opening and closing torque of bottle caps

- Digital / Manual

- Digital LCD

- Semi-automatic

- 25 kg

- 220 V AC

- Compliant with CE requirements

- 420 mm x 300 mm x 240 mm

- Stores up to 500 test results

- High-strength aluminum alloy

- < 30 W

- 10 - 150 mm diameter

- USB & RS232 ports

- Provided with traceable calibration certificate

- Automated electronic overload alarm

- Nm, kgf-cm, lbf-in selectable units

- Adjustable rubber grip jaws

Torque Measuring Machine Torque Testing Equipment for Bottle Cap Trade Information

- shenzhen,guangzhou

- 300 Set Per Month

- 7 Days

- All India

Product Description

Torque Measuring Machine Torque Testing Equipment for Bottle Cap

Digital bottle lid torque meter is an intelligent multi-functional measuring instrument which is designed for testing various kinds of bottle lid torque. It main used in testing and calibrating tighten force, parts torsional destructive testing, etc. With features of simple operation, high precision, easy to carry, complete functions etc. It is widely used in various kinds of electric, light industry, machinery manufacturing, research institutions, etc.

Main Features:

1)High precision, high resolution, quick sampling speed, full-screen display.

2)Adopting high precision torque sensor, with torque direction display.

3)Upper and lower limit value setting, red and green indicating lights and buzzer audible and visual alarm.

4)Three units can be switched each other (N.m, Kg.fcm, Lb.in).

5)Real-time, peak, automatic peak three models of optional switch.

6)Use USB interface and PC communications, synchronous test function can connect to the computer, computer synchronous display test force graph and the detailed test process, can save, print, doing all sorts of analysis.

7)Peak holding, remove automatically function, remove time to set freely.

8)Large storage, can save 99 groups of test data.

9)Without automatic shutdown function, time can be set freely.

Specification:

Model: ANL-P1

Printer: Yes

Measuring range/ Division value: 1.0000/0.0001N.m/ 10.200/0.001Kg.cm/ 8.850/0.001 Lb.in

Peak Value Sampling Frequency:2000HZ

Power: 7.2V 1.2VX6 Ni-MH Battery group

Charging Time: 4-6 Hours

Precise & Adjustable Cap Testing

Experience adaptable testing with rubber grip jaws and support for a wide range of cap sizes, allowing accurate evaluation of opening and closing torque for bottles, jars, and containers. The machine accommodates diameters from 10 to 150 mm and offers adjustable test speed for comprehensive analysis.

Traceable Calibration & Reliable Results

Each unit comes calibrated with a traceable certificate, ensuring compliance and repeatable accuracy. Storing up to 500 results, operators can rely on robust data management and easy export through USB and RS232 ports.

Advanced Safety and User-Friendly Operation

Automated electronic overload alarms and CE compliance enhance safety in every test. The digital/manual control modes and LCD display simplify operation, while high-strength aluminum alloy construction provides durability and stability during frequent daily testing.

FAQs of Torque Measuring Machine Torque Testing Equipment for Bottle Cap:

Q: How does the torque measuring machine accommodate different bottle cap sizes?

A: The machine is equipped with adjustable rubber grip jaws, allowing users to securely test bottle caps with diameters ranging from 10 to 150 mm. This flexibility makes it suitable for various bottles, jars, and container caps.Q: What is the process for calibrating the torque measuring equipment?

A: Each torque tester is provided with a traceable calibration certificate, ensuring accuracy. Calibration is performed according to international standards, and the machine maintains accuracy within 1% of the measured value.Q: Where can the data from torque tests be exported or used?

A: Data from up to 500 tests can be stored in the memory and exported via USB or RS232 ports. These outputs facilitate easy integration with laboratory software or quality control systems for further analysis and documentation.Q: When should overload protection be utilized during testing?

A: The equipment features an automated electronic overload alarm, which activates if the torque value exceeds safe limits during testing. This function prevents equipment damage and ensures operator safety.Q: What benefits does the semi-automatic control mode offer users?

A: Semi-automatic control, combining digital and manual operation, allows precise setting of test parameters while enabling user interventions where needed, optimizing efficiency and accuracy for cap torque measurement.Q: How does the machine contribute to quality assurance in packaging production?

A: By measuring the opening and closing torque of bottle caps consistently and accurately, the machine helps packaging manufacturers and suppliers maintain proper sealing and product integrity according to international safety standards.Q: What environmental conditions are recommended for operating the machine effectively?

A: The torque measuring instrument operates reliably within temperatures between 10C and 40C and humidity up to 85% RH, ensuring optimal performance in a variety of laboratory and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+