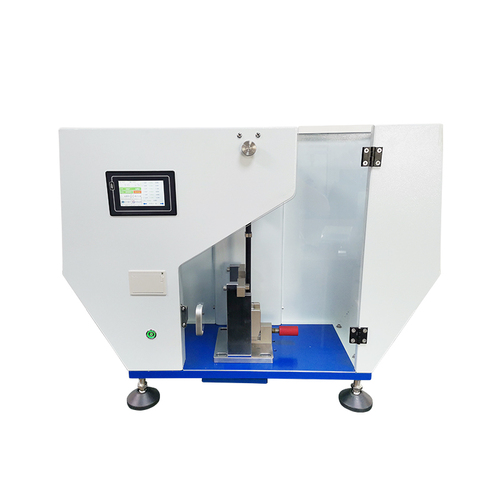

KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine

Product Details:

- Resolution 0.01 mm

- Response Time <1 s

- Gas Pressure 6-8 kg/cm

- Hardness Heavy Duty Construction

- Humidity 85%

- Test Range Up to 250 tons clamping force

- Accuracy 0.1 mm

- Click to view more

KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine Price And Quantity

- 5699.00 - 9999.00 USD ($)/Set

- 1 Set

- 350 mm

- 12-25 s

- 500 x 400 mm

- 5000 x 1500 x 3200 mm

- 450 L

- 18 kW

- 75 dB

- Thermoplastics, Engineering Plastics

- 55 kN

- 180 MPa

- 32 kW

- 200 mm

- 120 mm

- 760 g

- 60 mm

- 2500 kN

KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine Product Specifications

- 100-200 mm/s

- 85%

- Heavy Duty Construction

- PLC Automatic

- 350 mm

- 6-8 kg/cm

- <1 s

- 0.01 mm

- Single Cycle

- 1-250 tons

- Ethernet/USB

- Industrial, Commercial

- 380V

- Up to 250 tons clamping force

- 5-40C

- 0.1 mm

- 380V/50Hz

- 7500 kg

- Vertical Injection Molding Machine

- Digital + Touch Panel

- Max 500 x 400 mm

- 3.2 m

- 400 mm

- 3 Inch

- Plastic Product Manufacturing

- Floor Mounted

- 50 Hz

- Automatic

- Energy efficient, Large size, Servo motor control, Safety Interlock System

- 250 tons

- 350 mm

- 12-25 s

- 500 x 400 mm

- 5000 x 1500 x 3200 mm

- 450 L

- 18 kW

- 75 dB

- Thermoplastics, Engineering Plastics

- 55 kN

- 180 MPa

- 32 kW

- 200 mm

- 120 mm

- 760 g

- 60 mm

- 2500 kN

KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine Trade Information

- Shenzhen

- 30 Set Per Month

- 15 Days

- All India

Product Description

KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine

Application:

Applicable industries: plugs, sockets, connectors, switches, backpack buckles, chargers, electrical appliances, color palettes, hoses, hard tubes, soft boards, hard boards, mechanical parts, automobiles, meters, electronic parts, stationery, lampshades, Instrument shells, cabinets, computers, toothbrush handles, accessories, golf balls, corsages, antennas, badges, buttons, furniture, sports goods, decorations, glue flowers, small building materials, connectors, telecommunications, keychains, Toys, pens, cosmetic bottle joints, lenses, medical supplies, cams, zippers, daily products and other parts are injection molded.

Suitable for various thermoplastics: PC/ABS, PC, PS, PVC, PP, PU, PA, POM, PMMA, PET, PPO, PPS, ABS, PE, LCP, PBT, acrylic, melamine, 372, nylon , Polypropylene, polystyrene, etc.

Features:

1. It is more suitable for the molding of precision plastic parts: multi-stage temperature control, multi-stage injection pressure, shooting speed, and back pressure are multi-stage adjustable.

2. Vertical injection molding: four-column vertical clamping, vertical injection molding, suitable for insert molding and multi-purpose injection molding processes.

3. Save space: the size is 1.6m*1.0m*2.5m and the area is small.

4. Imported parts: imported parts are used for electric control parts and hydraulic parts, which are quiet, precise, durable and worry-free.

5. Convenient to detect and adjust: Intelligent rich controller, intelligent error report, easy to detect and adjust.

6. Easy to take out the finished product: The lower mold is fixed / the upper mold is movable, which has a good positioning of the molded insert in the mold. The finished product has a hydraulic ejector device, which is very convenient and easy to take out.

7. Intelligent safety design: fast mold clamping, adjustable low pressure safety mold locking, equipped with infrared protection function, touch infrared automatic pause to protect the personal safety of workers. Two-button start mode: the mold can be closed only by pressing the start button with both hands at the same time (press the start button with both hands, so that both hands are at the start button position and not under the mold), which ensures the personal safety of the workers.

Advanced Automation and Control

The KSU-250-ST utilizes PLC automatic controls and an intuitive digital touch panel, streamlining the molding process for improved productivity. Its responsiveness, with less than one second reaction time, minimizes cycle delays and enhances precise parameter management. Ethernet and USB interfaces allow seamless data connectivity, supporting process optimization and quality monitoring.

Robust Capabilities for Diverse Applications

Engineered for versatility, this vertical injection molding machine accommodates thermoplastics and engineering plastics in various industrial and commercial settings. Its substantial clamping force, spacious tie bar distance, and adjustable mold thickness make it suitable for manufacturing large, complex parts, ensuring accurate reproducibility and reliability over extended operations.

Energy Efficiency and Safety Features

Operating at 32 kW total power with an 18 kW heating system, the KSU-250-ST emphasizes energy-saving without compromising performance. Built-in safety interlock systems safeguard operators, and low noise levels (75 dB) contribute to a safer, more comfortable workspace. Its heavy-duty floor-mounted frame withstands rigorous usage while facilitating automation for streamlined production.

FAQ's of KSU-250-ST Large-sized Plastic Vertical Injection Molding Machine:

Q: How does the KSU-250-ST Injection Molding Machine enhance manufacturing efficiency?

A: The KSU-250-ST integrates automatic servo motor control and PLC automation, optimizing cycle speed and precision. With rapid response times and digital touch control, it reduces manual interventions and allows for accurate parameter settings, leading to improved output and consistency in production.Q: What types of materials can be processed with this machine?

A: This machine is compatible with both thermoplastics and engineering plastics, supporting a broad range of industrial and commercial applications. Its design allows for flexible processing of various resin formulations, improving versatility for manufacturers.Q: When should you use a large-sized vertical injection molding machine like the KSU-250-ST?

A: The KSU-250-ST is best utilized when manufacturing large or complex plastic components requiring substantial clamping force and injection capacity. It is ideal for high-volume production environments where automation and precision are critical for quality assurance.Q: Where can the KSU-250-ST be installed within a factory setup?

A: Designed for floor-mounted installation, the machine should be placed in a well-ventilated, humidity-controlled area (85% RH, 5-40C) with sufficient space for its dimensions (5000 x 1500 x 3200 mm), and access to a 380V/50Hz power supply. Proper placement ensures efficient workflow and maintenance access.Q: What is the process for operating the KSU-250-ST?

A: Operation begins with setting up the mold and configuring desired parameters on the PLC digital interface. After loading the raw material, the machine automatically performs the molding cycle, including injection, clamping, cooling, and ejection. Safety systems and interlocks protect operators throughout the process.Q: How can users benefit from the safety and efficiency features of this machine?

A: Users benefit from built-in safety interlocks that prevent hazardous operations, low noise emissions for improved working conditions, and energy savings due to the efficient heating and servo motor systems. These features foster a reliable and productive manufacturing environment.Q: What measurements and accuracy does the KSU-250-ST offer during production?

A: The machine provides digital measurement accuracy of 0.1 mm and a resolution of 0.01 mm, displayed clearly on its integrated touch panel. This precision enhances product quality and reduces material waste, supporting stringent manufacturing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+