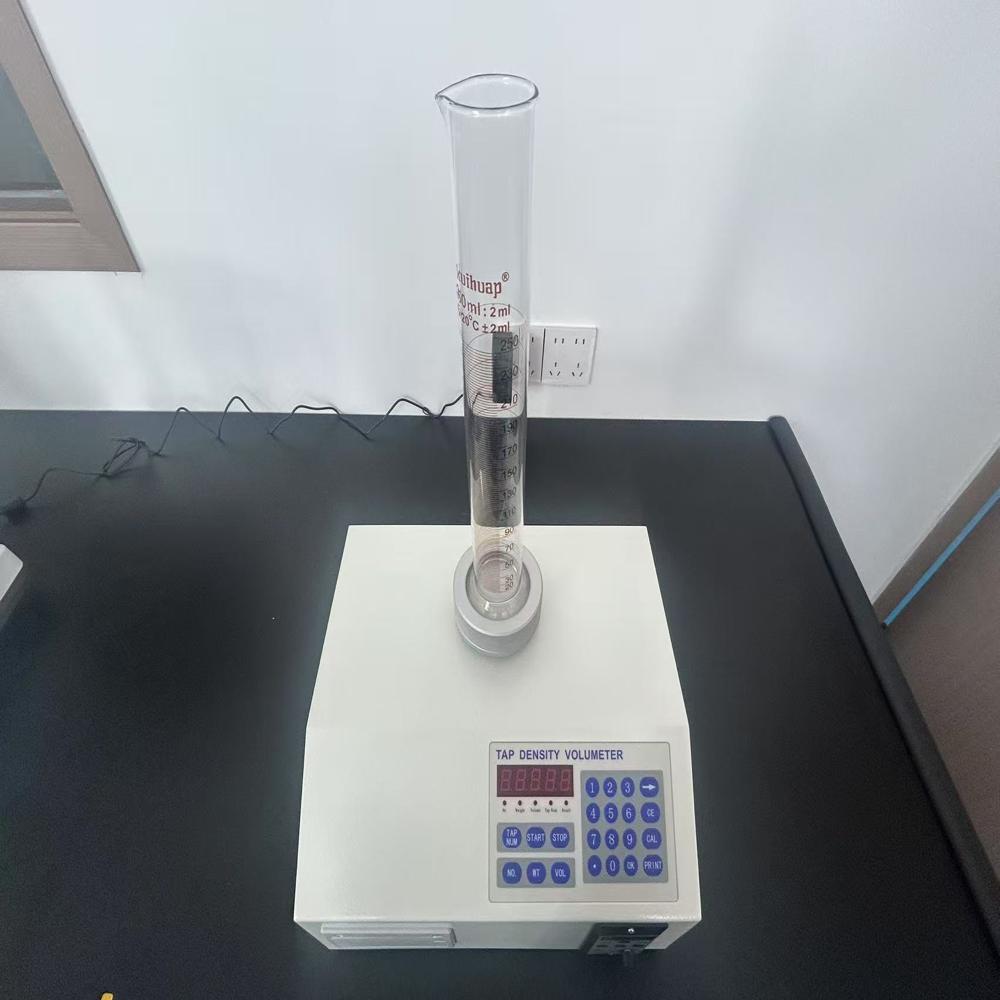

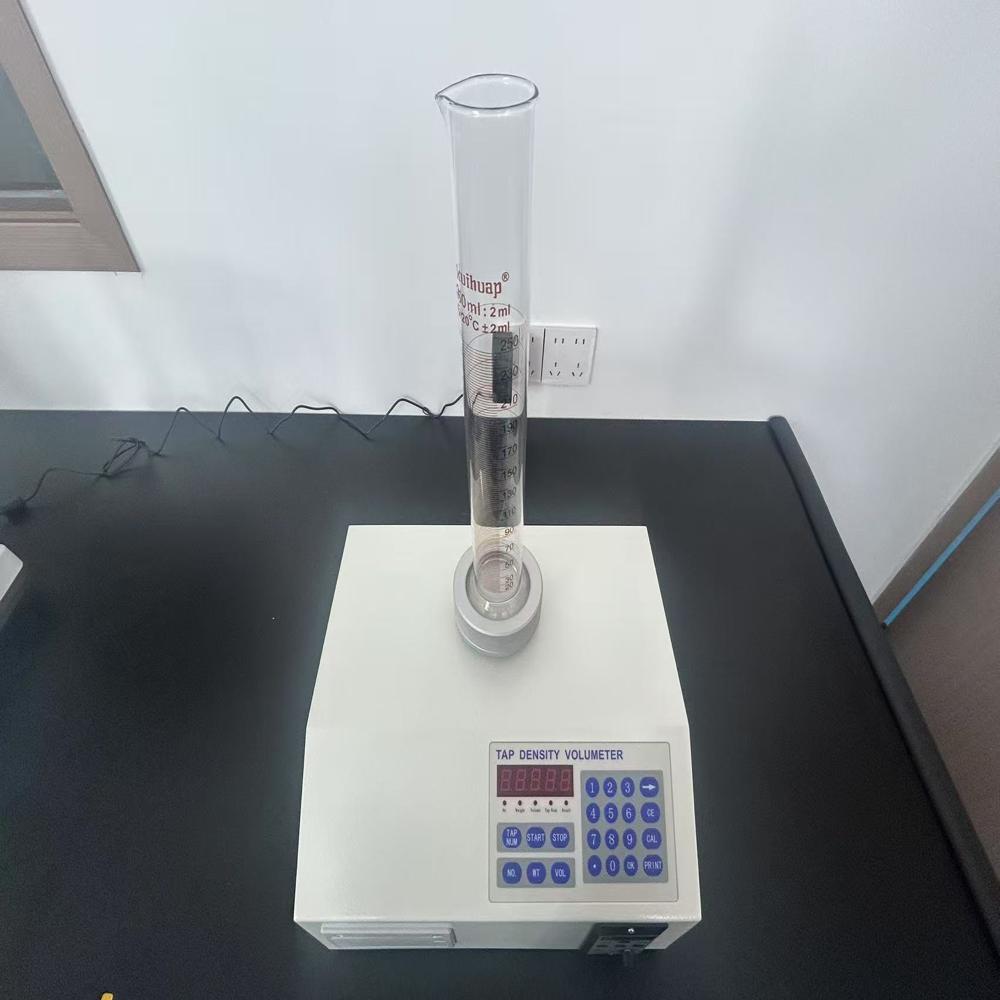

DY-100A Tap Density Tester to test powder

Product Details:

- Usage To test the density of the powder

- Power Supply 220V(50/60Hz),40W

- Voltage 220 Volt (v)

- Application powder

- Accuracy 1 %

- Test Range 500.00 g

- Machine Weight 20 Kilograms (kg)

- Click to view more

DY-100A Tap Density Tester to test powder Price And Quantity

- 1124.0 USD ($)/Set

- 1 Set

DY-100A Tap Density Tester to test powder Product Specifications

- 20 Kilograms (kg)

- 220 Volt (v)

- 220V(50/60Hz),40W

- To test the density of the powder

- 500.00 g

- 1 %

- powder

DY-100A Tap Density Tester to test powder Trade Information

- Shenzhen

- Telegraphic Transfer (T/T)

- 10 Set Per Week

- 7 Days

- Contact us for information regarding our sample policy

- Wooden box

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- CE, FCC

Product Description

Introduction:

DY-100A Powder density tester is based on GB/T5162-2006/ISO3953:1993(tap density measuring of metal powder).For non-metallic powder,This instrument extended several functions.

such as"vibration amplitude" from 3m standard extended to 1mm-15mm;"vibration frequency"from 100-300 times per minute extended to 0-300 times per minute."vibration times"from 3000 times standard extended to 0-99999 times.All of them can be setup freely.

DY-100A Powder density tester consist of adjustable-speed motor,vibration assembly,micro-computer and micro printer.,etc.It has the feature of compact structure,stable,and easy operation.,etc.

DY-100A Powder density tester consist of adjustable-speed motor,vibration assembly,micro-computer and micro printer.,etc.It has the feature of compact structure,stable,and easy operation.,etc.

Features:

1.Drop Height-Easily Adjustment

The drop height is important for a tap density tester in order to meet different international standards.This tap density tester uses default 3mm height and some tapping washers in specific height to reach 14mm.They changes easily without opening the cover.

2.Working Panel-Intuitive

The intuitive LED and membrane working panel brings operator and easy and fast operation.Accurate to 4 decimals.Automatically saving all test information.Operator simply inputs the desired data and press start to test.

3.Rpm-Easily Adjustment

The rpm is also important for a tap density tester.This instrument uses a speed control to realize 250rpm and 300 rpm.The motor is default 300 rpm,just tun the knob and reach the right percentage to shift to 250rpm.

4.Analysis Result-Easily Printed

Integrated micro printer prints the test data after test including Sample No,weight,volume,tap number,tap density and operator.

5.Cover-Easily to Clean

The outer surface is plastic coated,it is strong and resistant to any powders non-corrosive or corrosive.It makes for the cleaning procedure as well as a longer working life.

Specification:

(1) Weight of testing object:<=500.00g

(2) Volume of testing object:<=250.00ml(standard accessory including

25ml,50ml,100ml,250ml measuring cylinder)

(3) Single vibration times:<=0-99999 times(the result will come out as bulk density when input zero times)

(4) Allowable motor force:0.86 N.m.

(5) Vibration frequency:maximum 300 round per minute(0-300 round per minute is adjustable,USA pharmacopeia standard is 300 round per minute)

(6) Vibration amplitude:maximum 15mm(1mm-15mm is adjustable,International standard is 3mm)

(7) Repeatability error:<=1%

(8) Accuracy error:<=1%

Accurate Powder Density Measurement

The DY-100A Tap Density Tester provides highly precise density measurements for a wide range of powders. Its advanced design facilitates consistent results, making it a vital instrument in research and quality control environments. The machine supports a maximum sample size of 500 grams and achieves a 1% accuracy level.

Engineered for Industrial Versatility

Suitable for use in various settings, including laboratories, manufacturing plants, and quality control departments, this tester benefits powder manufacturers, distributors, exporters, and suppliers. It operates seamlessly with a standard 220V (50/60Hz) power supply and is compliant with industry standards.

Effortless Operation and Reliable Results

The machine's intuitive design streamlines the process of sample loading, testing, and result recording. With a sturdy 20 kg build, it minimizes vibration to ensure dependable readings, providing users with confidence in analytical outcomes and batch consistency.

FAQ's of DY-100A Tap Density Tester to test powder:

Q: How does the DY-100A Tap Density Tester determine the density of powder samples?

A: The DY-100A measures powder density by tapping a pre-measured powder sample within a graduated cylinder to a specified number of taps, then calculating the volume and dividing the known mass by the final volume, delivering accurate density results.Q: What types of powders can be tested with the DY-100A Tap Density Tester?

A: This device is suitable for a wide variety of powders, including pharmaceuticals, chemicals, food additives, and metallic powders, making it a versatile choice for different industries in India.Q: When should powder density testing be performed during the manufacturing process?

A: Density testing is recommended at various stages, such as raw material inspection, in-process control, and final quality assurance, to ensure material consistency and product quality.Q: Where can the DY-100A Tap Density Tester be used?

A: This tester is ideal for use in laboratories, manufacturing facilities, and quality control departments of powder producers, distributors, exporters, and suppliers throughout India.Q: What is the process of operating the DY-100A Tap Density Tester?

A: To use the machine, simply weigh the powder sample, load it into the cylinder, set the required number of taps, and start the test. The device will tap the sample, after which you can read and record the powder volume for density calculation.Q: How does using the DY-100A Tap Density Tester benefit powder manufacturers and suppliers?

A: It ensures batch-to-batch consistency, improves product quality, and helps manufacturers and suppliers meet regulatory and industry standards, enhancing trust and reliability among clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+