Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF

Product Details:

- Resolution 0.1 mm

- Number of Specimens 12

- Equipment Type Flexing Tester

- Features Automatic counting, programmable operation

- Automation Grade Automatic

- Gas Pressure 0.5 MPa

- Mounting Type Benchtop

- Click to view more

Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF Price And Quantity

- 979.00 - 2089.00 USD ($)/Set

- 1 Set

- Stainless Steel

- 800 × 400 × 360 mm

- Indoor

- 6-digit electronic preset counter

Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF Product Specifications

- 1-12 pairs

- 70 x 45 mm

- 0~999,999 Cycles

- 50 Hz

- Standard

- Test the flexing resistance of leather, shoes, fabrics

- Leather, shoes, cloth flex resistance test

- 12 Sets

- Instant

- 100 5 cpm

- Panel Control

- 220V

- 15%-85%RH

- 15C-40C

- 90 kg

- Test Block Hardness 752 Shore A

- Approx. 360 mm

- 0.1 mm

- 22.5 0.5 mm

- Digital (Electronic Control)

- 12

- Flexing Tester

- 0.1 mm

- 70 mm

- LCD Digital Display

- 0.5 MPa

- AC 220V, 50Hz

- Benchtop

- Automatic counting, programmable operation

- Automatic

- Stainless Steel

- 800 × 400 × 360 mm

- Indoor

- 6-digit electronic preset counter

Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF Trade Information

- Shenzhen

- 300 Set Per Month

- 7 Days

- All India

Product Description

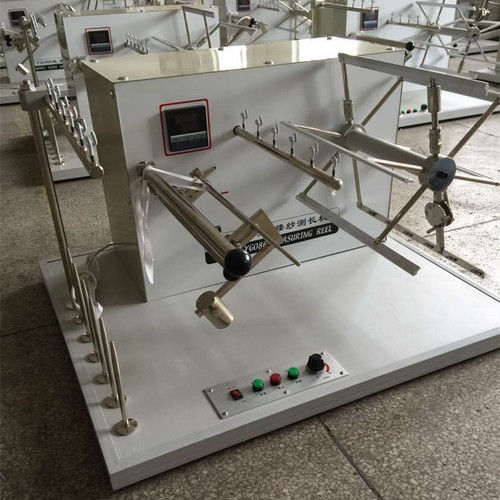

Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF

Summary

Leather scratch resistance tester is used to test the folding performance of various leathers and fabrics. Materials need to be nipped both inside and outside, twist and turn over and over again until a certain times, and cBally Leather Flexing Tester for Flexometer Test, Bally Leather Flexing Testerhecking the damage of the tested materials. The machine is mainly used in clothing, shoes, bags, etc.

Standards

ISO 17232 (IULTCS/IUP 38): Leather -- Physical and mechanical tests -- Determination of heat resistance of patent leather

ISO 20344: Personal protective equipment -Test methods for footwear

SATRA TM55: FLEXING RESISTANCE OF UPPER MATERIALS - BALLY FLEXOMETER

DIN 53351: Testing Of Artificial Leather And Similar Shut Materials - Behaviour At Permanent Folding

ISO 5402-1: specifies a method for determining the wet or dry flex resistance of leather and finishes applied to leather.

BS EN 344-1: Safety, protective and occupational footwear for professional use - Requirements and test methodsJIS K 6545: Testing method for flexing endurance of light leathers and their surface finishes

QB/T 2714: Leather - Physical and mechanical tests - determination of flex resistance

EN 13512: Footwear - Test Methods For Uppers And Lining - Flex Resistance

ETC...

Application

Used to test leather performance in shoes, clothing, luggage handbag industry, research laboratories; commodity inspection, arbitration and technical supervision departments.

Technical characteristics

Product name: Electronic Leather Scratch Resistance Testing Machine

Speed: 100 cpm

Fixture: 12 groups

Specimen Size: (70*45) mm

Bending Angle22.5 degree

Weight: About 60kg

Size: (52*64*40) cm

Power: AC220V, 50H

Advanced Flexing Resistance Testing

The Bally Leather Flexing Tester is engineered to provide highly accurate and consistent measurements of flex resistance in leather, shoes, and textiles. Its programmable features and easy panel interface make operation intuitive and efficient, supporting quality control and research needs. Automated cycle counting and instant LCD digital readout enhance productivity during extensive test routines.

Durable and Reliable Construction

Constructed with stainless steel specimen holders and a heavy-duty frame, the DH-LF model ensures long-lasting performance even under frequent usage. Designed for benchtop mounting, it suits laboratories, workshops, and industrial settings, reliably handling up to 12 specimens per run for comprehensive flex tests.

FAQ's of Bally Leather Flexing Tester Leather Flexoemeter for Shoes Cloth DH-LF:

Q: How does the Bally Leather Flexing Tester assess flex resistance in materials?

A: The Bally Leather Flexing Tester evaluates flex resistance by repeatedly bending specimens (up to 12 at a time) at a controlled test speed of 100 5 cycles per minute, using a programmable and automatic digital system to replicate real-world stress conditions. Results are measured via an LCD digital display for precise cycle counts and flexing distances.Q: What materials and products can be tested with this Flexoemeter?

A: This flexing tester is suitable for assessing leather, shoes, and textile fabrics. It provides valuable data on durability and flexibility, aiding manufacturers and suppliers in optimizing material selection for footwear and garment production.Q: When should flex resistance testing be performed using this equipment?

A: Flex resistance testing is recommended during product development, quality control, and routine manufacturing audits. It helps ensure that materials like leather and textiles meet specified performance standards for endurance and flexibility before reaching consumers.Q: Where is the Bally Leather Flexing Tester typically installed and operated?

A: It is designed for indoor operation and is commonly installed in laboratories, quality assurance departments, R&D centers, and production facilities due to its benchtop mounting and manageable footprint (800 400 360 mm).Q: What is the process for conducting tests with this equipment?

A: The process involves placing up to 12 specimens (each 70 45 mm) into the stainless steel holder, inputting test parameters, and starting the programmable test cycle. The automatic system records flex cycles and provides instant digital feedback. Test results are easily retrieved from the LCD display.Q: How does the use of this tester benefit manufacturers and suppliers?

A: Employing the Bally Leather Flexing Tester allows manufacturers to verify material durability, avoid faulty production, and meet international standards. This aids in ensuring product quality, reducing returns, and improving customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+