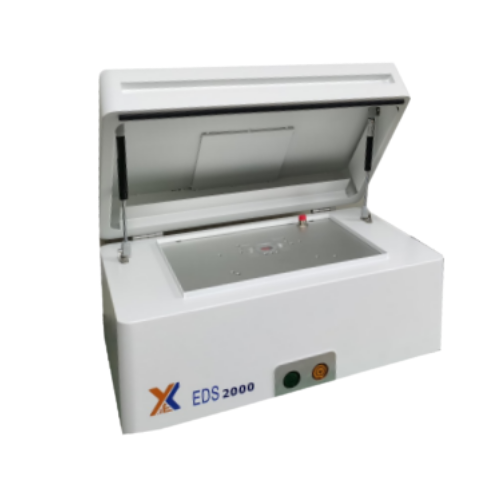

XRF Rohs Test Equipment XRF Spectrometer

Product Details:

- Features Non-destructive, Rapid detection, Easy software operation, Data storage, Auto-calibration

- Display Type Built-in LCD touchscreen

- Gas Pressure Ambient; no additional gas required

- Mounting Type Benchtop

- Temperature 10C 30C

- Port Size Standard USB, Ethernet

- Humidity 85% RH

- Click to view more

XRF Rohs Test Equipment XRF Spectrometer Price And Quantity

- 1 Set

- 9999.00 - 19999.00 USD ($)

XRF Rohs Test Equipment XRF Spectrometer Product Specifications

- 85% RH

- Standard USB, Ethernet

- Instantaneous (Results in under a minute)

- Electronic component testing, alloy analysis, plating detection

- 0.05%

- 2 mm - 120 mm (diameter or side length)

- Na (Sodium) to U (Uranium)

- 145 eV (at 5.9 keV)

- 220 V AC

- Non-destructive, Rapid detection, Easy software operation, Data storage, Auto-calibration

- 53 kg

- Fixed

- Ambient; no additional gas required

- Benchtop

- Built-in LCD touchscreen

- 10C 30C

- Automatic/PC-controlled

- 1 ppm to 99.99%

- Less than 60 seconds per sample

- AC 220V 10% 50/60Hz

- Up to 500 mm

- Single chamber, up to 350 samples/day

- RoHS Compliance, material analysis, hazardous substance detection

- Semi-automatic

- Single specimen at a time

- USB/Ethernet/RS232

- 40 mm (sample chamber)

- 50/60 Hz

- XRF Spectrometer

XRF Rohs Test Equipment XRF Spectrometer Trade Information

- shenzhen

- 30 Set Per Month

- 10 Days

- All India

Product Description

XRF Rohs Test Equipment XRF Spectrometer

RoHS is a compulsory standards set by the eu legislation, it is the full name of "about limit use of certain harmful components in electrical and electronic equipment directive(Restriction of Hazardous Substances).This standard has been started on July 1, 2006 formally implemented, it is mainly used for electrical product specification material and craft standard, make it more conducive to human health and environmental protection.The purpose of this standard is to eliminate electrical electronic products in the lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PCBS) and polybrominated diphenyl ether, a total of 6 substances, and the key specifies the amount of lead that the should not exceed 0.1%.

XRF ROHS Analyzer series advantages and characteristic:

- High resolution, high definition camera, convenient operation

- Nondestructive, rapid and accurate detection, human interface

- Heart of Europe,all core technologies from Europe and America

- Easy to use, one key operation, each element ROHS analysis results

- Test coating samples of innovative features

- The structure compact, appearance is very beautiful, suitable for placed on display room

- Press the button within seconds, can get the accurate results of the chemical composition of samples

- The use of PCS and software, can rapid conveniently make sample inspection result certificate

- Camera and cabin lighting system, real-time view sample testing, accomplish know fairly well

- Analyzer test data can be download and upload network detection results is easy to view and share

- And reliable power flow and short circuit protection, reliable to ensure the safety of the user

- Automatic test system of control, reliable guarantee of customers to use

Instrument performance and configuration

- Analysis:1 PPM to 100%

- Precision RSD: 0.01% -0.05%

- Test samples of physical: state of solid, liquid and powder

- Light tube voltage: 5 kv - 50 kv/optional import light tube

- High voltage power supply :0-50 kv Spellman (USA)

- Light control current: 0 mu A -1000 mu A

- Camera: high-definition cameras

- Detector: Si Pin/SDD (optional)

- Resolution: Si - pin145 + 5 ev /SDD135 + 5 ev (USA)

- Multichannel analyzer: DMCP

- Test time: 200SEC - 600SEC

- ROHS analysis common elements: Pb, Hg, Br, Cr, Cd, Ba, Sb, As..Etc.

- Analysis software: FP qualitative quantitative analysis software

Advanced Technology for Reliable Results

With a high-resolution Si-PIN or SDD detector and a 50 kV excitation source, the XRF Rohs Test Equipment offers unparalleled accuracy and rapid results for various testing applications. The machines wide test range, from sodium (Na) to uranium (U), enables detailed elemental analysis. Its automatic calibration and user-friendly software streamline operations, making it ideal for laboratories and manufacturing environments focused on compliance and quality.

Efficient, Safe, and User-Friendly Operation

This spectrometer incorporates full lead shielding and safety interlocks for robust operator protection. The air-cooled design keeps maintenance demands low, while the built-in touchscreen and versatile connectivity (USB, Ethernet, RS232) ensure seamless integration into your workflow. Automated processes and simple data management allow for high throughput with up to 350 samples analyzed per day.

FAQs of XRF Rohs Test Equipment XRF Spectrometer:

Q: How does the XRF Rohs Test Equipment analyze materials for RoHS compliance?

A: The spectrometer uses a 50 kV X-ray tube and a high-resolution Si-PIN or SDD detector to non-destructively scan and identify hazardous substances in electronic components and materials, delivering results that support compliance with the RoHS directive.Q: What types of samples can be tested and what are the specimen size requirements?

A: This equipment can test single specimens at a time, with allowable sample sizes ranging from 2 mm to 120 mm in diameter or side length, and a maximum sample height of 40 mm, making it suitable for a wide range of components and alloys.Q: When is calibration required and how is it performed?

A: The system supports both automatic and standard sample calibration. Calibration can be performed on startup or at regular intervals to ensure continuous measurement accuracy, all managed easily through the user-friendly software interface.Q: Where is XRF Rohs Test Equipment typically installed and who can use it?

A: Designed as a benchtop model, this spectrometer is suitable for laboratories, quality control departments, manufacturing facilities, and third-party testing environments involved in electronics, materials analysis, and compliance verification.Q: What is the process for running a test and obtaining results?

A: Simply place the specimen in the stainless-steel chamber, initiate the automated test via the built-in LCD touchscreen or PC software, and receive detailed results and compliant reports in under 60 seconds. Data can be exported in CSV, PDF, or custom formats for documentation.Q: How does using this spectrometer benefit manufacturers and suppliers?

A: Manufacturers and suppliers gain fast, reliable detection of hazardous substances, streamlined RoHS compliance, and high throughputup to 350 samples a dayimproving product quality, reporting accuracy, and overall operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+