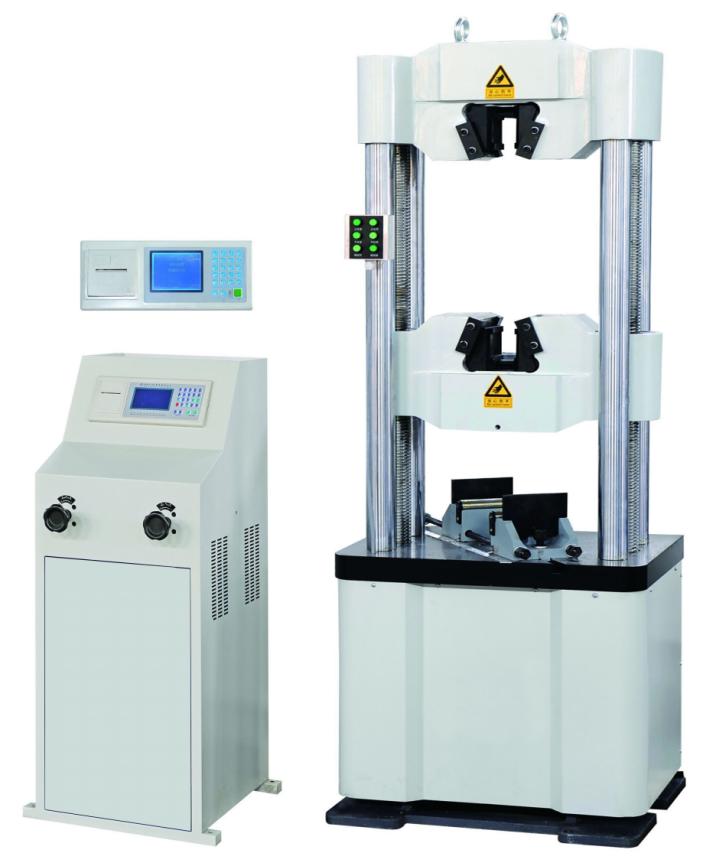

Rubber Tensile Testing Machine

Product Details:

- Test Range 2kN/ 200kg

- Product Type Single Column Computer Controlling Servo Universal Testing Machine

- Click to view more

Rubber Tensile Testing Machine Price And Quantity

- 1699.0 USD ($)/Set

- 1999.00 - 3999.00 USD ($)/Set

- 1 Set

Rubber Tensile Testing Machine Product Specifications

- 2kN/ 200kg

- Single Column Computer Controlling Servo Universal Testing Machine

Rubber Tensile Testing Machine Trade Information

- shenzhen or guangzhou

- 300 Set Per Month

- 5 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

Rubber Tensile Testing Machine

This machine is a new material testing machine combining electronic technology with software technology and mechanical transmission. It adopts imported AC servo electric and AC servo speed control system as precision power source. It adopts imported precision ball drive screw and guide rod, adopting imported grade 0.5. The precision force value sensor is then accurately measured by a high-precision force value measurement system. This series of models adopts single space structure, which is mainly used for material testing with load less than 10kN. It has firm structure, convenient operation and simple maintenance. It is an ideal test instrument for mechanical testing in various factories and enterprises. It has a wide and accurate loading speed and force range. It has high precision and sensitivity for measurement and control of load, deformation and displacement. It has stress, strain and displacement modes, and can find the maximum force value, tensile strength and bending strength, compression strength, modulus of elasticity, elongation at break, yield strength and other parameters, suitable for tensile, compression, peeling, tearing, shearing, etc. mechanical properties test and analysis.

Application industry:

Rubber and plastics; metrological quality inspection; commodity inspection and arbitration; technical supervision department; colleges and universities; scientific research laboratory; basic materials laboratory; metallurgical steel; machinery manufacturing; electronic appliances; automobile production; textile chemical fiber; wire and cable; packaging materials and food; Instrumentation; medical equipment; petrochemical; civil nuclear energy; aerospace; ceramic materials; magnetic materials industry; energy batteries; basic materials;

Standard:

ASTM, ISO, DIN, GB and other international standards.

Main Feature:

- Meet most of the mechanical properties test

- Completely compact structure, high rigidity design, durable

- Easy to operate, anyone can operate

- High accuracy, certified by a third-party testing agency

- High speed, low vibration, low noise motor drive

- Multilingual application function, adapt to different countriesa using

- Capabilities with graph, data sheet, report viewing and printing

- Automatic returning function after test completed

- Automatic calculation of maximum force, minimum force, average force, maximum deformation, elongation, strength, etc.

- Has a variety of curve modes such as stress-strain, force-displacement, force-time, intensity-time

- Has test mode functions such as tensile, flexural, compressive, flexural, adhesive, tear, peel, elongation, etc.

- With mechanical travel switch; emergency stop switch; over current, over voltage, under current, under voltage, leakage overload protection; software overload limit protection; breakpoint shutdown protection and other multiple protection devices

- Optional: small deformation metal extensometer, large deformation displacement tracker

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+