Plastic Melt Flow Rate Index Tester MFI Testing Device

Product Details:

- Frequency 50 Hz

- Application Testing melt flow index (MFI) of plastic materials such as PP, PE, ABS, etc.

- Temperature Ambient to 400C (PID controlled)

- Specimen Size Standard granule, pellet or powder

- Test Range 0.1 to 999.9 g/10 min

- Operating Voltage 230V AC

- Automation Grade Semi-automatic / Fully automatic (based on model)

- Click to view more

Plastic Melt Flow Rate Index Tester MFI Testing Device Price And Quantity

- 899.00 - 1799.00 USD ($)

- 1 Set

Plastic Melt Flow Rate Index Tester MFI Testing Device Product Specifications

- Semi-automatic / Fully automatic (based on model)

- 230V AC

- 1 at a time

- PID temperature control, corrosion resistant sleeve, auto-cut off, user-friendly, overheat protection

- Plastic Melt Flow Rate Index Tester

- Approx. 600 mm

- Benchtop

- 230V AC, 50Hz, Single Phase

- Instant (on test completion)

- Manual / Digital (depending on model)

- Standard Barrel, 9.55 mm ID

- 0.01 g/10 min

- Less than 85% RH (non-condensing)

- 0.1999.9 g/10 min

- Microprocessor based digital control

- 0.01 g

- Digital LED/LCD display

- 50 Hz

- 2 kg, 5 kg & 10 kg dead weights (as per models)

- Ambient to 400C (PID controlled)

- Testing melt flow index (MFI) of plastic materials such as PP, PE, ABS, etc.

- Standard granule, pellet or powder

- Standard as per ISO 1133 / ASTM D1238

- Plastic laboratories, QC labs, R&D Centers

- Approx. 20 kg

- 0.1 to 999.9 g/10 min

- Manual / Motorised (as per model)

Plastic Melt Flow Rate Index Tester MFI Testing Device Trade Information

- shenzhen

- 300 Set Per Month

- 7 Days

- 41*51*61cm;41kg;standard exported wooden package

- All India

- CE, FCC

Product Description

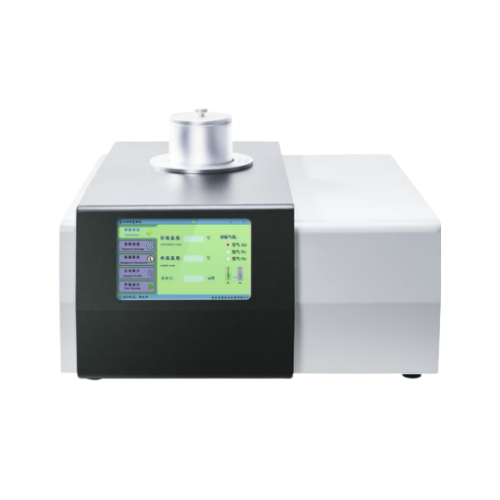

Plastic Melt Flow Rate Index Tester MFI Testing Device

Model:DH-MI-BP

The melt flow rate meter is a special instrument for determining the melt flow rate of a thermoplastic under certain conditions. It refers to a molten material extruded from a die of a specified length and diameter under a certain temperature and load. Mass flow rate MFR or melt volume flow rate MVR, which can distinguish the viscous flow characteristics of thermoplastics in molten state; it is of great significance for the quality assurance of thermoplastics and chemical fiber raw materials, products, etc., especially in quality. Inspection and warehousing testing.

This series of melt indexer is specially designed for fast and accurate measurement. It has the characteristics of firm structure, easy operation, stable and reliable performance. It uses high-precision PID thermostat technology, high temperature control precision, nitriding of key parts, high strength and hardness. The thermal expansion deformation is small. DH-MI-BP,DH-MI-VP is a regular model, manual loading weight with automatic cutting function; DH-EI-BP,DH-EI-VP is the model with an electric loading weight with automatic cutting function.which means the weights is placed on the weight bracket in advance for electric loading and unloading, reducing manual operation. The DH-AI-VP is a fully automatic model with automatic loading weight and automatic cutting function, which automatically loads and unloads the corresponding weight according to the set mode.to further improve measurement efficiency.

Usage:

It is used to determine the melt mass rate flow rate MFR value or melt volume rate flow rate MVR value of various plastics and resin polymers in the viscous flow state. It is suitable for polycarbonate, polyarylsulfone,fluoroplastics and nylon which has higher melting temperature.It is also suitable for polyethylene (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyoxymethylene (POM), and polycarbonate (PC) resins.which has lower melting temperatures

Remarks: Testing fluorine material is optional

Application industry:

Plastics industry; rubber industry; metrological quality inspection; colleges and universities; research institutes; commodity inspection and arbitration, technical supervision departments; petrochemicals; electrical appliances; composite materials;and other industries.

According to the standards:

The melt flow rate meter is suitable for the determination of the mass flow rate of thermoplastic melts specified in the national standard GB/T3682.1-2018 Determination of melt flow rate and melt volume flow rate of thermoplastics. It adopts the ISO 1133 regulations and meets the ASTM D1238 test standard. It complies with JB/T5456 "Melt Conditioner of Melt Flow Rate Meter" and JJG 878 - "Melt Flow Rate Meter" standard specification.

Specification:

Brand: DahoMeter

Model: DH-MI-BP

Weight loading method: Manual

Testing result: Mass / MFR

Standard test load: A total of 8 full set of weights

Temperature control range: Room temperature-400 degree (Optional-500 degree)

Accurate Plastic Melt Flow Rate Analysis

Engineered for high accuracy, this MFI testing device ensures precise determination of plastic melt flow properties according to ISO 1133 and ASTM D1238 standards. The PID-controlled heating chamber, digital display, and versatile stroke options provide excellent adaptability for different types of plastics. Laboratories benefit from rapid, reliable results with longevity ensured by durable stainless steel and high-grade steel components.

User-Friendly Operation and Safety

Operation is simple with an intuitive microprocessor interface, preset digital timer, and auto-cut off features. The equipment is equipped with overheat protection and a corrosion-resistant sleeve, enhancing safety and lifespan. The manual or motorized options for stroke and cutting mechanisms provide flexibility depending on user preferences or test requirements.

FAQs of Plastic Melt Flow Rate Index Tester MFI Testing Device:

Q: How is the Plastic Melt Flow Rate Index Tester used to measure MFI?

A: The tester is used by loading standard granules, pellets, or powder into the stainless steel barrel and selecting the required weight. The material is then melted at a set temperature, and the flow rate is measured by either a manual or motorized mechanism, as per ISO 1133 or ASTM D1238 standards. The digital control ensures temperature stability, and the result is displayed instantly upon test completion.Q: What types of plastics can be tested with this MFI device?

A: This equipment is suitable for a wide range of thermoplastic polymers, including polypropylene (PP), polyethylene (PE), acrylonitrile butadiene styrene (ABS), and similar materials. Its universal design and compatible accessories allow easy adaptation for various sample types.Q: When should the tester be calibrated or maintained?

A: Routine calibration and maintenance are recommended as per the laboratorys quality protocols or after extensive use. Always clean the barrel and piston with the provided tools after each test to prevent residue buildup and ensure accurate, repeatable results.Q: Where is this tester commonly used?

A: The Plastic Melt Flow Rate Index Tester is widely used in plastic laboratories, quality control labs, and R&D departments for materials analysis, specification checks, and production monitoring.Q: What is the benefit of having both manual and motorized operation modes?

A: The option to select between manual and motorized operation enables users to tailor the testing approach based on throughput, operator preference, or specific testing requirements. Motorized versions can improve consistency and reduce operator fatigue during repetitive testing.Q: How does the device ensure testing accuracy and safety?

A: The device features PID-controlled temperature regulation for precision, user-friendly interfaces, automatic cut-off, and overheat protection. Its corrosion resistant sleeve and robust steel construction further enhance test integrity and operator safety.Q: What accessories are included with the tester?

A: Standard included accessories comprise weights (2 kg, 5 kg, and 10 kg), piston, orifice, cleaning tools, and an instruction manual, ensuring users have everything necessary for immediate and effective operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+