Welcome to Our Company

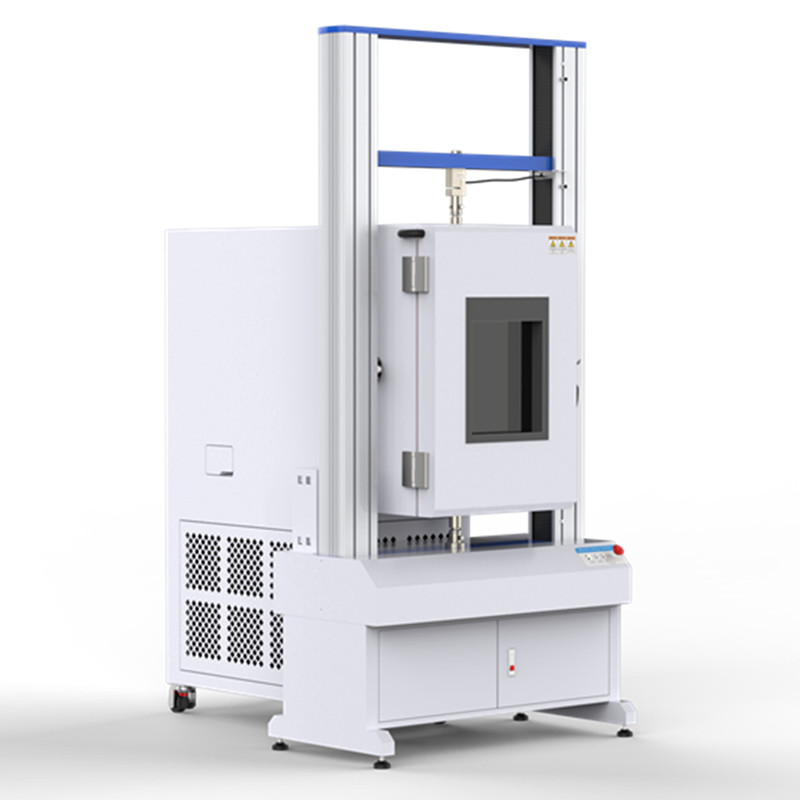

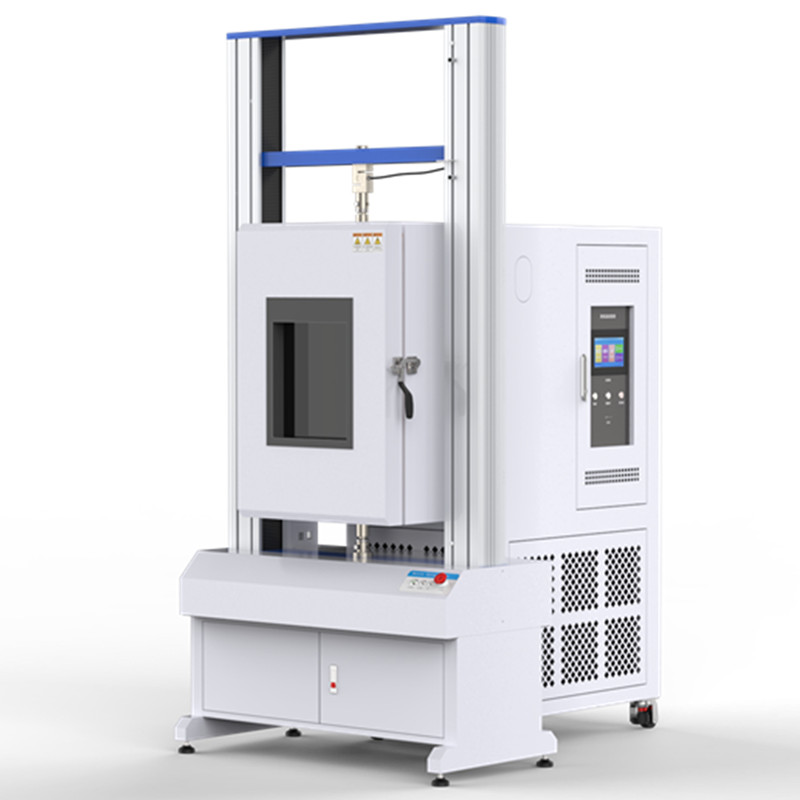

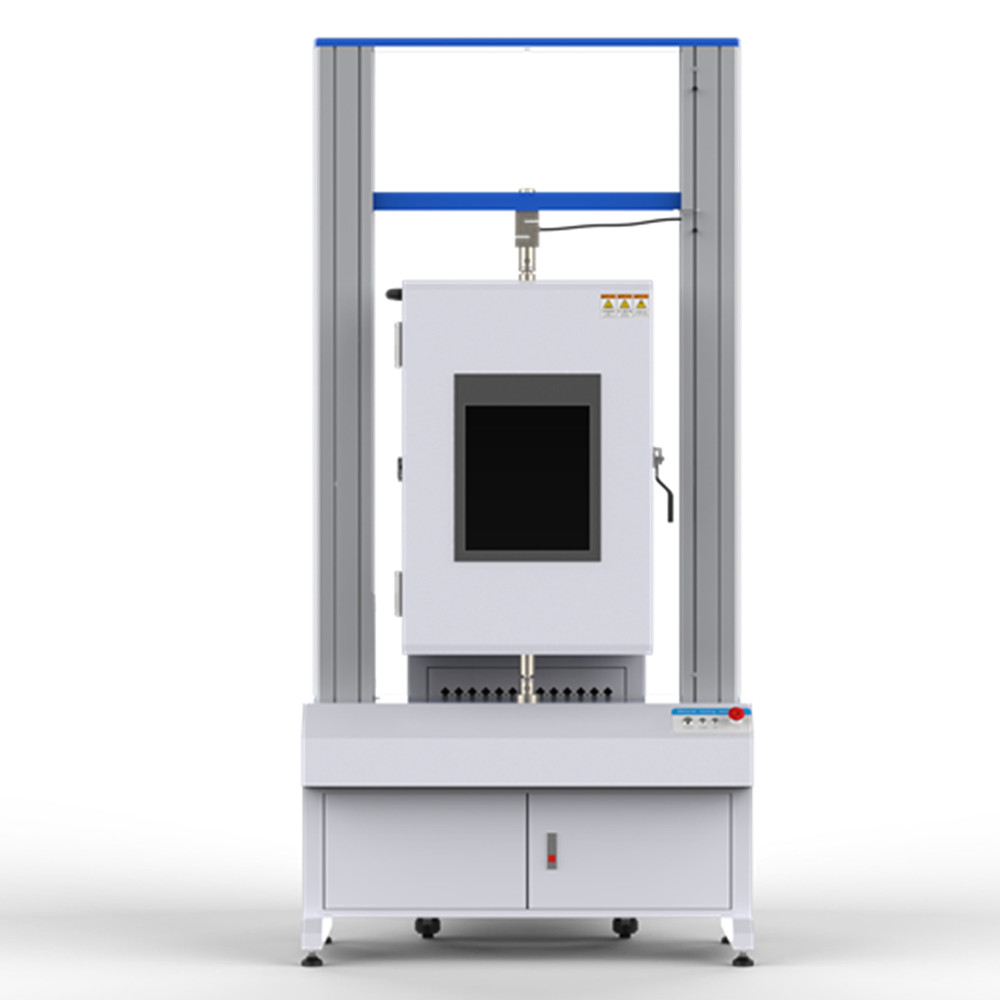

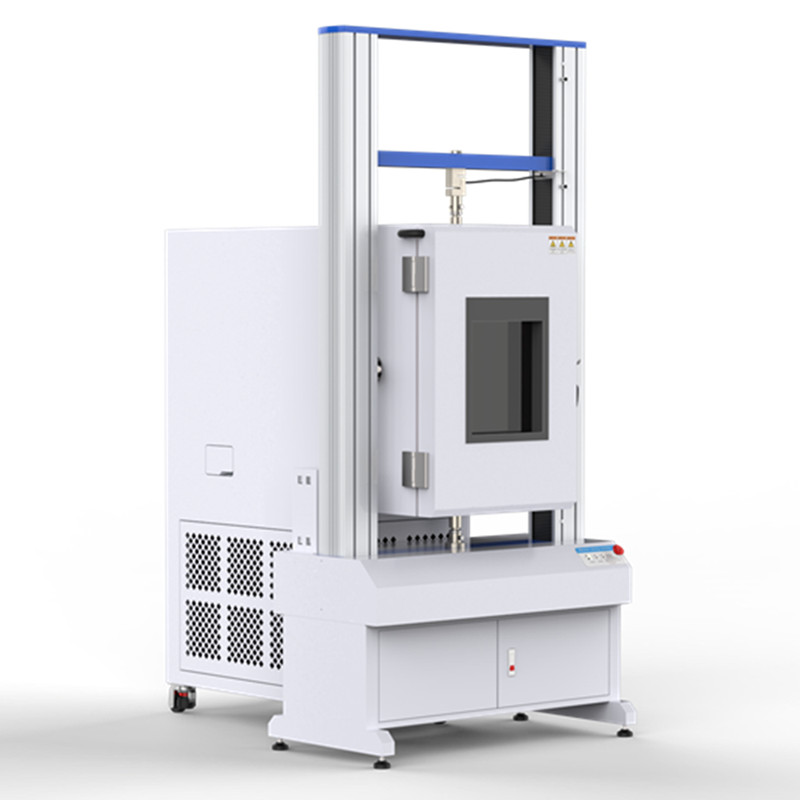

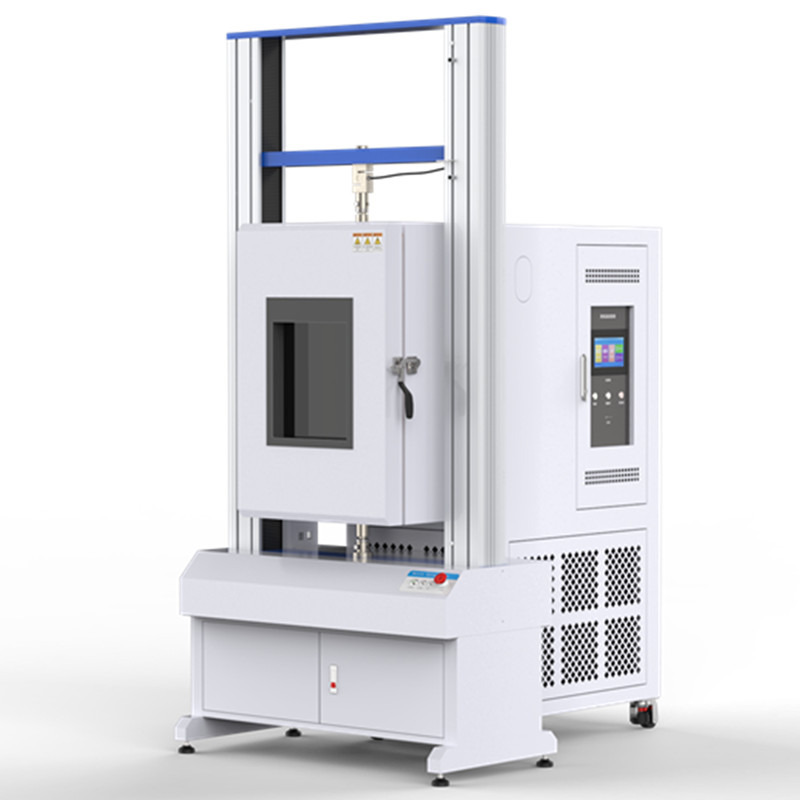

HT-GDW Microcomputer Controlled High and Low Temperature Electronic Universal Testing Machine

8102.0 USD ($)/Set

Product Details:

- Voltage 220-240 Volt (v)

- Material MS

- Operate Method Automatic

- Usage Industrial

- Product Type Single Column Touch Screen Universal Testing Machine

- Power Supply Electric

- Test Range 10KN / 1000kg

- Click to view more

X

HT-GDW Microcomputer Controlled High and Low Temperature Electronic Universal Testing Machine Price And Quantity

- 8102.0 USD ($)/Set

- 1 Set

HT-GDW Microcomputer Controlled High and Low Temperature Electronic Universal Testing Machine Product Specifications

- Industrial

- Automatic

- MS

- 220-240 Volt (v)

- Single Column Touch Screen Universal Testing Machine

- 10KN / 1000kg

- Electric

HT-GDW Microcomputer Controlled High and Low Temperature Electronic Universal Testing Machine Trade Information

- shenzhen

- Telegraphic Transfer (T/T), Western Union

- 300 Set Per Month

- 7 Days

- standard exporting package

- All India

- CE, FCC

Product Description

HT-GDW Microcomputer Controlled High and Low Temperature Electronic Universal Testing Machine

Standards

1. GB/T 2611-2007

2. JB/T 7406.1-1994

3. GB/T 16491-2008

4. GB/T 16825.1-2008

5. GB/T 22066-2008

6. JJG 139-1999

7. JB/T 6146-2007

8. JB/T 6147-2007

9. GB/T 228.1-2010

10. GB/T 7314-2005

11. GB/T 232-2010

12. Other non-metal testing standards

Technical Instructions

| Brand | HONGTUO | ||

| Model | HT-GDW | ||

| Detail Model | -5KN | -10KN | |

| Capacity | KN | 5 | 10 |

| KG | 500 | 1000 | |

| lb | 1102 | 2204 | |

| Sensor | The USA | ||

| Servo motor | Panasonic | ||

| Unit switching | GKglbNKN | ||

| Displacement unit switch | Inch cm mm | ||

| Testing machine level | 0.5 class | ||

| Effective force measuring range | 0.2100FS | ||

| Force accuracy | Within 0.5% of the indication value | ||

| Force resolution | 1/500000 | ||

| Displacement resolution | 0.05m | ||

| Displacement accuracy | Within 0.5% of the indication value | ||

| Deformation measurement range | 0.2%100%FS | ||

| Deformation indication accuracy | Within 0.5% of the indication value | ||

| Large deformation measurement range | 1000mm (optional) | ||

| Large deformation resolution | 0.01mm (optional) | ||

| Large deformation indication error limit | Within 0.5% of the indication value (optional) | ||

| Maximum test speed | 500mm/min, optional maximum 1000mm/min | ||

| Minimum test speed | 0.01mm/min | ||

| Speed accuracy | Within 0.5% of the indication value | ||

| Crossbeam stroke measurement height | Test stroke without fixture: 1330mm; test stroke with fixture: 800mm | ||

| Effective width | 750mm | ||

| Fixture configuration | One set of film stretching clamps and one set of 180 degree peeling clamps | ||

| Return method | Two options: manual or automatic, automatically return to the initial position after the test or manually return to the initial position | ||

| Shutdown mode | 1. Automatic shutdown at the maximum breaking value | ||

| 2. Shutdown with upper and lower safety limit settings | |||

| Safety devices | 1. Mechanical travel switch protection | ||

| 2. Emergency stop switch emergency braking | |||

| Overload protection | When the load exceeds 100%, the machine automatically protects | ||

| Accessories | 1 power cord, 1 test software program, 1 data cable, 1 instruction manual, 1 certificate | ||

| Optional accessories | Anti-splash device (protective door), computer, printer, small deformation metal extensometer, large deformation extensometer | ||

| Supply voltage | 220V AC/ 50Hz (Can be selected according to country110V AC/60Hz) | ||

| Host size/Weight | Model including base: (Length*Width*Height)800mm*750mm*2100mm / about 205KG | ||

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email