Digital Charpy Impact Tester Charpy Impact Testing Equipment

Product Details:

- Specimen Size 55 x 10 x 10 mm

- Test Range Up to 300 Joules

- Max Height 1250 mm

- Response Time Instantaneous

- Display Type Digital LCD Display

- Humidity 85% RH

- Temperature 10C to 40C

- Click to view more

Digital Charpy Impact Tester Charpy Impact Testing Equipment Price And Quantity

- 1 Set

- 699.00 - 2119.00 USD ($)

- Calibrated as per ASTM E23/ISO 148

- 900 mm x 400 mm x 1250 mm

- Pendulum Guard, Emergency Stop

- Blue & Grey

- Internal Memory with Export Option

- Powder Coated

- Wooden Case

- Manual Specimen Placement

- 150°

- Low

Digital Charpy Impact Tester Charpy Impact Testing Equipment Product Specifications

- Impact Testing of Metals

- Digital LCD Display

- Instantaneous

- 1250 mm

- Up to 300 Joules

- 55 x 10 x 10 mm

- 10 mm

- 10C to 40C

- 85% RH

- 300 Joules

- USB/Data Output

- 220 V AC

- 0.01 Joule

- Bench-top

- Robust MS Body

- 0300 J

- Automatic Data Calculation, Auto Stop, User-Friendly Interface

- 160 kg

- 5.2 m/s

- Full Swing

- Standard

- Digital Charpy Impact Tester

- Single Specimen Per Test

- Semi-Automatic

- Metallurgical, Quality Control, Research Laboratories

- 220 V AC, 50/60 Hz

- Digital Control

- 50/60 Hz

- 0.5% of Reading

- Calibrated as per ASTM E23/ISO 148

- 900 mm x 400 mm x 1250 mm

- Pendulum Guard, Emergency Stop

- Blue & Grey

- Internal Memory with Export Option

- Powder Coated

- Wooden Case

- Manual Specimen Placement

- 150°

- Low

Digital Charpy Impact Tester Charpy Impact Testing Equipment Trade Information

- shenzhen

- 300 Set Per Month

- 7 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

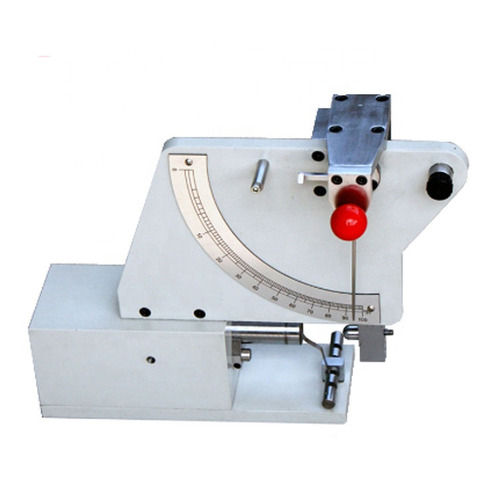

Digital Charpy Impact Tester Charpy Impact Testing Equipment

Application:

This series of digital impact testing machine is mainly used for the

determination of impact toughness of non-metallic materials such as rigid plastics, reinforced nylon, FRP, ceramics, cast stone, electrical insulating materials, etc. It is the ideal testing equipment for the chemical industry, research institutes, universities, quality inspection, etc.

Features:

1. This series of impact testing machine is an intelligent digital display impact testing machine developed by micro-computer technology. It can automatically correct the energy loss caused by friction and wind resistance, and get rid of the numerical chart of energy correction due to the influence of resistance. (The detection of the residual energy of the pendulum and the correction of the energy loss after the sample breaks are completed once in the impact process).

2. This series of impact testing machines adopts electronic display test results to make the readings more intuitive and improve the accuracy and accuracy of the impact machine.

3.Using rotary encoder garden grating angle measurement technology, with advantage of high precision, good stability and large measurement range, digital displaying the thrust energy, impact strength, pre-elevation angle, elevation angle, average value, and energy loss automatic correction.

4.The swing arm is made of new carbon fiber material, the strength is higher than steel, and the weight is lighter than aluminum.

Standards:

The main technical parameters are in full compliance with the requirements of IS0 179-2000, GB/T 1043-2008, JB/T 8762-1998, GB/T 1451-2005, GB/T18743-2002

Specification:

Model: HT-1043-25D

Pendulum energy: 7.5J, 15J, 25J

Test angle: 150

Impact speed: 3.8m/s

Pendulum center distance: 380mm

Impact blade angle: 30

Jaw support spacing: 40mm, 60mm, 70mm, 95mm

Support blade corner radius: R=1mm

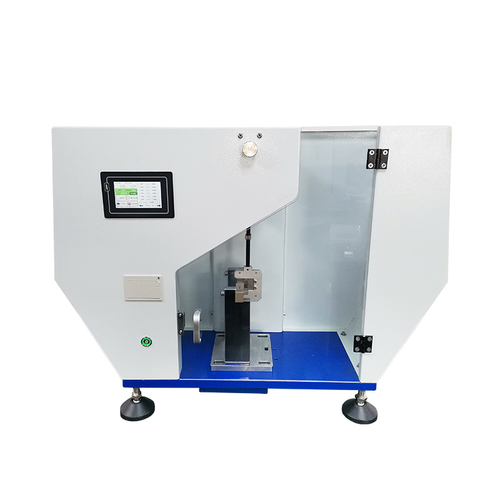

Advanced Safety and User-Friendly Features

This Charpy impact tester incorporates both a pendulum guard and an emergency stop function, ensuring user safety during operation. The intuitive digital control panel and automatic data calculation tools create an efficient workflow, allowing users to focus on test accuracy. The bench-top mounting and compact dimensions make it suitable for a variety of laboratory environments.

Precision Testing with Reliable Data Management

The equipment promises exceptional measurement accuracy at 0.5% of reading, with a wide energy capacity up to 300 Joules. Instantaneous response time coupled with internal memory and USB export options guarantee secure and convenient data handling. The digital LCD readout presents results clearly and promptly, supporting precise metallurgical evaluations.

FAQs of Digital Charpy Impact Tester Charpy Impact Testing Equipment:

Q: How does the Digital Charpy Impact Tester operate?

A: Operation involves manual specimen placement followed by activating the pendulum, which swings at a test speed of 5.2 m/s. The impact energy absorbed by the specimen is measured instantly and displayed on the digital LCD panel. The machine supports single specimen tests per cycle for precise evaluation.Q: What safety features are included in this equipment?

A: The tester is equipped with a pendulum guard to prevent accidental contact during tests and has an emergency stop button for immediate halt in case of any irregularity, ensuring operator safety throughout operation.Q: When should calibration be performed, and what standards does the tester follow?

A: Calibration is done as per ASTM E23 and ISO 148 standards, typically before initial use and periodically thereafter, depending on laboratory protocols. This guarantees measurement reliability and compliance with industry requirements.Q: Where can this impact testing equipment be used?

A: The tester is highly suited for metallurgical labs, quality control departments, and research institutions. Its semi-automatic, bench-top design and moderate size make it adaptable for both teaching and industrial applications.Q: What is the data management process in this machine?

A: Test data are stored in the internal memory allowing later retrieval, and can be easily exported via a USB/data output interface for analysis or archiving. The system features automatic data calculation and auto-stop functions for streamlined operation.Q: How does using this digital tester benefit laboratory operations?

A: Benefits include enhanced accuracy due to digital measurement and instant response, superior data handling, and improved safety. The equipment provides reliable, quick results and reduces manual calculation errors, increasing laboratory productivity.Q: What are the recommended environmental conditions for optimal equipment performance?

A: The impact tester operates efficiently within a temperature range of 10C to 40C and humidity less than or equal to 85% RH. Maintaining these conditions ensures consistent measurement accuracy and preserves equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+