Repose Angle Measurement Instrument

499.00 - 999.00 USD ($)

Product Details:

- Interface Type Manual/Analog reading

- Display Type Analog/Graduated Scale

- Equipment Type Repose Angle Measurement Instrument

- Frequency 50 Hz

- Temperature 10C to 50C (operating range)

- Gas Pressure Ambient pressure (not required)

- Accuracy 1

- Click to view more

X

Repose Angle Measurement Instrument Price And Quantity

- 499.00 - 999.00 USD ($)

- 1 Set

Repose Angle Measurement Instrument Product Specifications

- 1

- Manual

- Up to 200 g powder

- 230 V AC, 50 Hz

- 1

- Ambient pressure (not required)

- Fixed platform stroke

- 10C to 50C (operating range)

- 100 mm platform width

- 50 Hz

- Repose Angle Measurement Instrument

- Manual/Analog reading

- Analog/Graduated Scale

- 230 V AC

- Material Science, Pharmaceuticals, Food Industry, Research Labs

- 50-100 g powder sample

- Single Sample per Test

- Standard 6 mm pipe connection

- Manual Operation (User Controlled)

- Manual

- 0 to 90

- 5% to 85% RH, non-condensing

- 0 to 90

- Anti-corrosive finish, easy to clean, portable design

- Approx. 15 kg

- Benchtop

- Immediate (manual measurement)

- Mild Steel Body, Powder Coated

- Measurement of angle of repose for powders and granules

- 100 mm cone height

Repose Angle Measurement Instrument Trade Information

- shenzhen or guangzhou

- 300 Set Per Month

- 7 Days

- All India

Product Description

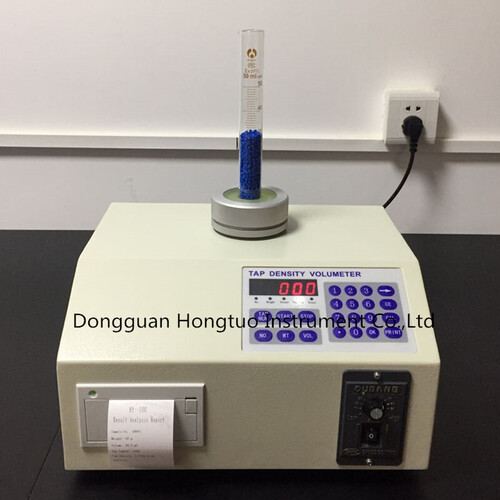

Repose Angle Measurement Instrument

The angle of repose is the angle (relative to the horizontal base) of the conical pile produced when a granular material is poured on to a horizontal surface. It is related to the density, surface area and coefficient of friction of the material concerned.

DF-1-05 repose angle tester is designed and produced based on ISO 4324:1997.

Structure:

(1)Funnel(diameter of outflux:5mm)

Taper of funnel: 60 degree

(2)Protractor

10cm

(3) Chassis

The distance between chassis and outflux: 80mm

Diameter of tray: 80mm

(4)Repeated error: less than or equal to 1%

Robust Construction and Design

Built from powder-coated mild steel, the instrument guarantees durability and corrosion resistance, maintaining reliable operation even in high-humidity environments. Its smooth finish and removable parts allow for quick and simple cleaning, minimizing downtime and keeping the platform ready for subsequent tests.

Precision Measurements for Laboratory Needs

Engineered for accuracy, the instrument offers a 0 to 90 measuring range with 1 accuracy and 1 resolution. The analog graduated scale ensures rapid, reliable readings, and the easy-to-use manual interface is accessible to all laboratory technicians, regardless of technical background.

Versatile Applications Across Industries

Ideal for material science, pharmaceutical, food, and research labs, this benchtop instrument measures the flow characteristics of various powders and granules. Its manual operation and portable design make it suitable for diverse testing conditions, supporting quality control and research objectives efficiently.

FAQs of Repose Angle Measurement Instrument:

Q: How is the Repose Angle Measurement Instrument operated?

A: This instrument utilizes a manual control system, operated entirely by hand. Users place a powder or granule sample (typically 50100 g) onto the flat, removable platform and use the integrated manual cone lifter to form a powder cone. The repose angle can then be read directly from the high-contrast graduated scale.Q: What materials is the instrument constructed from, and how does this benefit the user?

A: The unit is made from mild steel with a powder-coated, anti-corrosive finish, delivering durability and resistance to corrosion. This ensures a long lifespan for the instrument, even in laboratory environments with varying humidity and temperature.Q: When should the flat, removable platform be cleaned, and how is this done?

A: The platform should be cleaned after each test or when changing between different powder samples to prevent cross-contamination. Simply remove the platform and wipe it with a lint-free cloth; mild cleaning agents can be used if necessary.Q: Where can the instrument be installed or used?

A: Owing to its compact benchtop design, the instrument can be set up in any laboratory or research facility equipped with a standard 230 V AC supply. It is suitable for use in environments with temperatures from 10C to 50C and relative humidity of 5% to 85% (non-condensing).Q: What key processes are involved during repose angle measurement?

A: The main steps include loading a pre-weighed powder/granule sample onto the test platform, manually forming a cone using the lifter, leveling the device with the screws, and then reading the angle of repose from the analog graduated scale for immediate results.Q: What are the advantages of using a manual repose angle measurement instrument?

A: The manual interface removes reliance on electronic components, reducing maintenance needs and simplifying operation. The analog system provides instant, accurate measurements, while the removable parts facilitate easy cleaning and prevent material contamination.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email