MFR Melt Flow Index Tester

Product Details:

- Features Microprocessor-based PID control, timer, buzzer alert, auto-cut off

- Max Height Approx. 420 mm

- Display Type Digital/LED Display

- Gas Pressure Ambient atmospheric pressure (for reference)

- Mounting Type Laboratory bench top

- Measuring Range 0.150 g/10 min

- Operating Voltage 230 V

- Click to view more

MFR Melt Flow Index Tester Price And Quantity

- 1 Set

- 2689.00 - 6599.00 USD ($)

- 0 to 9 minutes, Digital

- SS-304 Stainless Steel

- Electric resistance heater

- 2.16kg, 5kg, optional others

- Double-layer ceramic insulation

- Made of hardened tool steel, 2.095mm inner diameter

- Over-temperature protection and alarm

- Approx. 320 x 250 x 480 mm

- Manual or Motorized cutter (as per configuration)

MFR Melt Flow Index Tester Product Specifications

- Up to 80% RH, non-condensing

- 0.1C (Temperature Control)

- 0.1 to 50 g/10 min (depending on material and load)

- Single test per cycle

- Manual plunger stroke: 30 mm

- 230 V

- 0.150 g/10 min

- Laboratory/Industrial testing of plastic granules

- Laboratory bench top

- Approx. 420 mm

- Digital/LED Display

- Ambient atmospheric pressure (for reference)

- Microprocessor-based PID control, timer, buzzer alert, auto-cut off

- Digital (with microprocessor control)

- 0.1C (Temperature), 0.01 g (Weight)

- Semi-Automatic

- 3-4 grams (typical granule load)

- Standard manually controlled as per test protocol

- 230 V AC, 50 Hz

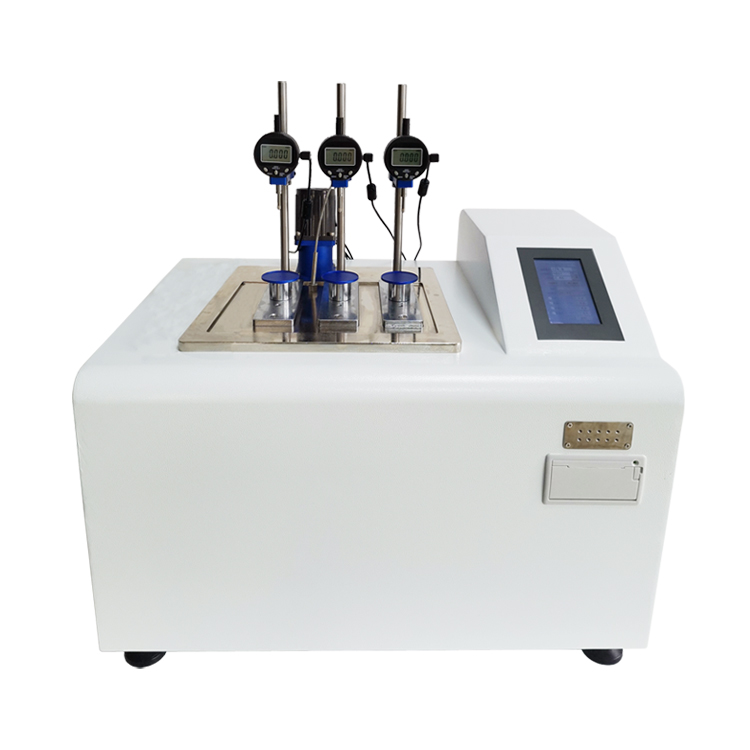

- MFR Melt Flow Index Tester

- Standard orifice diameter: 2.095 mm

- 50 Hz

- Up to 400C, up to 21.6 kg load

- Determination of melt flow rate of thermoplastics

- <5 seconds (temperature stabilization)

- Ambient to 400C (adjustable)

- Keypad/Touch Panel

- Approximately 21 kg

- 0 to 9 minutes, Digital

- SS-304 Stainless Steel

- Electric resistance heater

- 2.16kg, 5kg, optional others

- Double-layer ceramic insulation

- Made of hardened tool steel, 2.095mm inner diameter

- Over-temperature protection and alarm

- Approx. 320 x 250 x 480 mm

- Manual or Motorized cutter (as per configuration)

MFR Melt Flow Index Tester Trade Information

- Shenzhen

- 300 Set Per Month

- 7 Days

- Standard exporting wooden package

- All India

- CE, FCC

Product Description

MFR Melt Flow Indexer Comply with ASTM D1238 and ISO 1133 , Melt Flow Index Testing Equipment For Plastic

The melt flow rate meter is a special instrument for determining the melt flow rate of a thermoplastic under certain conditions. It refers to a molten material extruded from a die of a specified length and diameter under a certain temperature and load. Mass flow rate MFR or melt volume flow rate MVR, which can distinguish the viscous flow characteristics of thermoplastics in molten state; it is of great significance for the quality assurance of thermoplastics and chemical fiber raw materials, products, etc., especially in quality. Inspection and warehousing testing.

This series of melt indexer is specially designed for fast and accurate measurement. It has the characteristics of firm structure, easy operation, stable and reliable performance. It uses high-precision PID thermostat technology, high temperature control precision, nitriding of key parts, high strength and hardness. The thermal expansion deformation is small. DH-MI-BP,DH-MI-VP is a regular model, manual loading weight with automatic cutting function; DH-EI-BP,DH-EI-VP is the model with an electric loading weight with automatic cutting function.which means the weights is placed on the weight bracket in advance for electric loading and unloading, reducing manual operation. The DH-AI-VP is a fully automatic model with automatic loading weight and automatic cutting function, which automatically loads and unloads the corresponding weight according to the set mode.to further improve measurement efficiency.

The Main Feature of DH-AI-VP

- This model is a fully automatic model. The stepping motor drives the ball screw to rotate to achieve the purpose of automatically controlling the top loading weight to rise or fall.

- Multi-stage (3 sections) temperature control mode, 3 sets of platinum resistance sensors, 3 heating sets for independent temperature control, high-precision intelligent PID control, and the temperature rise slope is the temperature rise rate adjustable;

- Built-in temperature stability warning alarm, and increase the 240 second material preheating second countdown specified in GB/T3682. After the countdown is finished, a beep sounds, and the preheating time such as American standard ASTM D1238 can also be set;

- Built-in test conditions for melt index of plastic materials, which are convenient for customers to use at any time, reduce the cumbersome workload, and store the last test conditions and results;

- Using sensitive 7-inch touch screen controller, it can store and print the latest test conditions and data. The test print menu settings include test time (system default), operator, material name, test method, test condition (temperature, weight weight). , cutting time interval), test result data, test results artificially judge OK or NG;

- Reserve RS232 interface or USB interface to connect to the computer, which can control the operation of the instrument and save the test data to the computer through the computer;

- Support all international test standards and methods, including ISO 1133, ASTM D1238, GB/T3682 and other national standards or international standards organization standards.

Specification:

Model: DH-AI-VP

Weight loading method: Automatic

Testing result: Mass and volume / MFR and MVR

Standard test load: A total of 8 full set of weights

Temperature control range: Room temperature -500 degree

Measuring range: 0.1-100g/10min

Power supply: AC220V / 50HZ or AC110V /60HZ; Choose different power supply voltages

Net weight: 48KG

Gross weight: 63KG

Accurate and Reliable MFR Testing

Utilizing hardened tool steel orifices and microprocessor PID controls, the MFR Melt Flow Index Tester delivers consistent and reliable results for the melt flow rate of thermoplastics. Its precise temperature and weight measurement systems ensure trustworthy data essential for quality control in plastics manufacturing or research laboratories.

Flexible Operation and User-Friendly Design

Choose between manual and motorized cutters to match your testing protocol and operator preference. The digital interface, featuring keypad or touch panel operation, streamlines test setup and monitoring. Single specimen cycles with adjustable timings allow seamless adaptation for various polymer types.

Safety and Efficiency Combined

Double-layer ceramic insulation and over-temperature alarms are integrated to maximize operator safety and ensure efficient thermal retention. The systems buzzer alerts, automatic cut-offs, and sturdy SS-304 construction make it a dependable choice for high-volume and routine testing in demanding environments.

FAQs of MFR Melt Flow Index Tester:

Q: How does the MFR Melt Flow Index Tester determine the melt flow rate of thermoplastics?

A: The tester extrudes a heated thermoplastic specimen through a standard orifice under a controlled load, measuring the mass of polymer that flows out over a set time period. The result, expressed in grams per 10 minutes, indicates the melt flow rate.Q: What materials and specimen sizes are suitable for this equipment?

A: The tester is ideal for plastic granules and similar thermoplastic materials. Typical specimen sizes are 3-4 grams, and the instrument supports single test cycles per loading.Q: When should I opt for the motorized cutting mechanism over the manual one?

A: The motorized cutter is recommended when high repeatability or frequent testing is required, minimizing variability due to operator interaction. The manual cutter is suitable for lower sample throughput and offers cost-effectiveness for occasional use.Q: Where is this tester best installed?

A: Designed for benchtop mounting, it is suitable for laboratory and industrial testing environments. Place it on a stable, flat surface with access to 230V AC power, ensuring adequate ventilation and away from excess moisture (up to 80% RH, non-condensing).Q: What is the process for conducting a test with this instrument?

A: Load the selected weight onto the plunger after filling the heated barrel with the specimen. Set the desired temperature and timer, then start the test. Extruded material is cut at intervals per protocol, and mass is recorded for MFR calculation.Q: What are the main benefits of using a microprocessor-controlled MFR tester like this model?

A: Users benefit from improved repeatability, precise temperature regulation, fast stabilization (<5s), digital monitoring, and built-in safety features. These enhance test reliability and operator safety, streamlining both routine and compliance-based testing in quality assurance processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+