Powder Angle of Repose Testing Machine

499.00 - 999.00 USD ($)

Product Details:

- Temperature 10C 40C

- Features Easy cleaning, robust construction, quick changeover

- Port Size 50 mm

- Measuring Range 0 60

- Humidity 10% 90% RH (non-condensing)

- Hardness Not applicable for powder material

- Equipment Type Powder Angle of Repose Testing Machine

- Click to view more

X

Powder Angle of Repose Testing Machine Price And Quantity

- 1 Set

- 499.00 - 999.00 USD ($)

- Digital export to PC or printer

- Indoor laboratory conditions

- Stainless Steel (main test chamber & components)

- Overload protection, emergency stop

- Standard, detachable

- Meets ASTM and ISO standards for powder testing

Powder Angle of Repose Testing Machine Product Specifications

- 50 mm

- Variable, 0.5 10 mm/s

- 10% 90% RH (non-condensing)

- 0 60

- 10C 40C

- 250 mm

- Easy cleaning, robust construction, quick changeover

- Laboratory testing

- Semi-automatic

- 50 Hz

- Measurement of powder flow property and angle of repose

- Manual / Digital

- Not applicable for powder material

- Powder Angle of Repose Testing Machine

- 150 mm

- Benchtop

- <2 seconds

- 0.5

- 230 V AC, 50 Hz

- Up to 100 mm

- 230 V AC

- USB / RS232 (optional)

- 0.01

- Up to 120 mm

- 15 kg

- 0.5 1.0 MPa

- 1

- 0 90

- Digital/LED

- 500 g 2 kg

- Digital export to PC or printer

- Indoor laboratory conditions

- Stainless Steel (main test chamber & components)

- Overload protection, emergency stop

- Standard, detachable

- Meets ASTM and ISO standards for powder testing

Powder Angle of Repose Testing Machine Trade Information

- shenzhen or guangzhou

- 300 Set Per Month

- 7 Days

- All India

Product Description

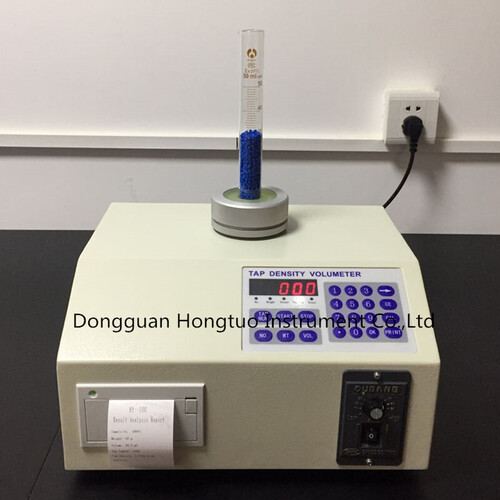

Powder Angle of Repose Testing Machine

The angle of repose is the angle (relative to the horizontal base) of the conical pile produced when a granular material is poured on to a horizontal surface. It is related to the density, surface area and coefficient of friction of the material concerned.

DF-1-05 repose angle tester is designed and produced based on ISO 4324:1997.

Structure:

(1)Funnel(diameter of outflux:5mm)

Taper of funnel: 60 degree

(2)Protractor

10cm

(3) Chassis

The distance between chassis and outflux: 80mm

Diameter of tray: 80mm

(4)Repeated error: less than or equal to 1%

Advanced Measurement Capabilities

Offering a measurement range of 060 with a high accuracy of 0.5 and resolution of 0.01, the machine is suitable for characterizing a wide variety of powder materials. Its rapid response time of less than 2 seconds ensures seamless laboratory workflows.

User-Friendly Design and Controls

Equipped with manual and digital control modes, easy-to-clean detachable funnels, and a quick changeover mechanism, the system is engineered for convenience. Digital export options via USB or RS232 streamline data analysis and reporting.

Compliance and Reliable Safety

The device fully complies with ASTM and ISO powder testing standards, making it suitable for use in regulated laboratories globally. Features like overload protection and an emergency stop guarantee safe operation for both operator and equipment.

FAQs of Powder Angle of Repose Testing Machine:

Q: How does the Powder Angle of Repose Testing Machine measure powder flow and angle of repose?

A: The machine uses a standard, detachable funnel to pour powder into the stainless steel test chamber. Through variable-speed controls, the powder forms a pile whose angle is digitally measured with high precision, providing accurate and repeatable flow property data.Q: What materials and specimen sizes can be tested with this equipment?

A: The machine accommodates powders with capacities ranging from 500 g to 2 kg and specimen sizes up to 100 mm, making it suitable for most laboratory-scale powder flow assessments.Q: When is powder angle of repose testing conducted in the laboratory?

A: Angle of repose testing is typically performed during quality control, new material development, or when evaluating powder flow characteristics for process optimization or regulatory compliance.Q: Where is this machine best utilized?

A: This equipment is designed for indoor laboratory environments requiring stable temperatures (10C40C) and humidity (10%90% RH, non-condensing). Its benchtop design is ideal for analytical and materials testing labs.Q: What is the process for exporting data from the device?

A: After completing a test, data can be digitally exported to a PC or printer using the devices USB or RS232 interface. This facilitates efficient documentation and reporting of laboratory results.Q: How do the safety features protect users during operation?

A: The machine includes overload protection and an emergency stop to immediately halt operation in the event of any issue, ensuring the operators safety and preventing equipment damage.Q: What benefits do digital controls and displays provide for powder testing?

A: Digital/LED displays enable accurate, real-time readings, while digital export simplifies data management. These features enhance testing efficiency, reliability, and traceability in laboratory workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email