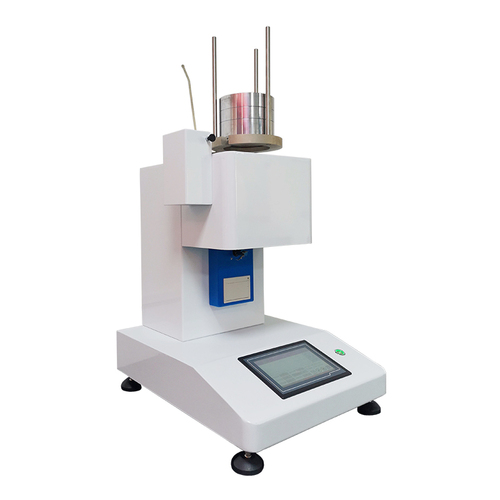

Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester

Product Details:

- Number of Specimens Single specimen per test

- Humidity 85% RH, non-condensing

- Test Range For plastic pipes, diameter 32 mm315 mm

- Features Automatic release, digital setting, quick specimen fixture

- Resolution 0.01 J

- Automation Grade Automatic

- Hardness Hammer: 50 HRC (approx.)

- Click to view more

Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester Price And Quantity

- 2199.00 - 4399.00 USD ($)

- 1 Set

- Corrosion-resistant enamel

- Mechanical (standard), digital (optional)

- 70 dB(A) during operation

- Manual log (optional electronic system available)

- Approx. 900 mm 800 mm

- Transparent acrylic safety cover, interlock system

- Heavy-duty powder coated steel

- D90, D250 (as per pipe size and standards)

- Adjustable V-block for different pipe sizes

- ISO 3127, IS 4984, ASTM D2444

Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester Product Specifications

- 85% RH, non-condensing

- Single specimen per test

- Automatic release, digital setting, quick specimen fixture

- Touch screen PLC automatic control

- 5 J 80 J impact energy (with interchangeable hammers)

- For plastic pipes, diameter 32 mm315 mm

- 0.01 J

- Automatic

- Laboratory and industrial pipe impact quality control

- 0.1 J

- Hammer: 50 HRC (approx.)

- Single drop per cycle

- Digital LCD Touch Panel

- AC 220V, 50 Hz

- Not required (gravity drop operation)

- RS232/USB data output

- Drop Hammer Impact Testing Machine

- Approximately 180 kg

- Up to 400 mm

- 1500 mm hammer drop height

- 0.8 m/s 2.5 m/s adjustable

- Pipe length up to 500 mm

- Impact resistance test of plastic pipes (PVC, PE, PP, etc.)

- Compatible with 32 mm to 315 mm pipes

- 10C to 35C

- AC 220V, 50 Hz

- <1 second

- Max. 1500 mm

- 32 mm to 315 mm pipe diameter

- Floor standing

- Corrosion-resistant enamel

- Mechanical (standard), digital (optional)

- 70 dB(A) during operation

- Manual log (optional electronic system available)

- Approx. 900 mm 800 mm

- Transparent acrylic safety cover, interlock system

- Heavy-duty powder coated steel

- D90, D250 (as per pipe size and standards)

- Adjustable V-block for different pipe sizes

- ISO 3127, IS 4984, ASTM D2444

Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester Trade Information

- shenzhen

- 300 Set Per Month

- 10 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester

Product introduction:

It is suitable for the determination of impact toughness of PVC-U, PVC-C pipe, PP pipe, PE pipe, plastic pipe for underground communication pipe, etc. It is an ideal test instrument for testing, production company, building materials industry and scientific research institution. The control part of the test machine adopts PLC, touch screen operation display, high automation, digital preset and display impact height, lift hammer and drop hammer; anti-secondary impact by adopting pneumatic transmission device, and the secondary impact capture rate is 100%. With personal safety automatic protection device (sample room door safety protection, anti-shock safety protection, etc.)

Standards:

It meets the technical requirements of the industry standard JB/T9389 ,and meets the test methods of GB/T14152, GB/T10002.1, GB/T5836.1, GB/T13664, GB/T16800, ISO4422, ISO3127, BSEN1411, BSEN744.

Product features:

1.The working table can be adjusted, which has the function of automatically returning to zero position and automatically go up and down.

2.It has the anti secondary impact device, which can prevent the hammer secondary impact by sample elastic force after the first impact.

3.The lifting mechanism uses the induction brakes and chain transmission, which make lifting steady and reliable.

4.It use the impact PLC as the control element to control the height of lifting hammer, and automatically measure the height of the hammer head with accurate position.

5.The device can automatically locate, zero, lift hammer, grasp hammer after impact. The high standard of automatization makes it easy to operate.

6.It uses the polished rod as the guiding device, with little resistance when hammer falls.

7.It can add safety protection device to ensure the operation safety.

Technical parameters:

Operating temperature: 10-35 degree;

There is no large vibration source nearby, no strong electromagnetic field;

There is no corrosive medium in the environment, and the electric control box should be well ventilated;

Workbench stroke: 0-400mm;

Hammer head: d25, d90;Note: (SR5, SR10, SR30) are optional according to user requirements;

Impact height: 0-2000mm;

Dimensions(length* width*height): 730mmx700mmx3700mm;

Weight of the whole machine: about 550kg.

Advanced Safety and Precision Engineering

Equipped with a transparent acrylic safety cover and robust interlock system, the machine prioritizes operator safety while ensuring accurate test results. Its adjustable V-block fixture allows for secure and precise accommodation of a broad spectrum of pipe sizes, making it exceptionally versatile for different testing needs.

User-Friendly, Automated Operation

This impact testing machine features automatic PLC touch screen control and digital LCD display, simplifying test operations and data monitoring. Users can digitally set parameters, automatically release the drop hammer, and quickly secure specimens, making the process streamlined for both laboratory and industrial settings.

Compliance and Versatile Application

Compliant with ISO 3127, IS 4984, and ASTM D2444, this machine meets major international standards for plastic pipe impact testing. Suitable for a variety of materials like PVC, PE, and PP, it is an excellent choice for product quality control by manufacturers, distributors, exporters, and laboratories.

FAQs of Plastic Pipe Drop Hammer Impact Testing Machine Pipe Impact Tester:

Q: How does the Plastic Pipe Drop Hammer Impact Testing Machine operate?

A: This machine uses a gravity-driven hammer, automatically released via a touch screen PLC, to deliver controlled impact energy onto a pipe specimen secured in an adjustable V-block. The safety cover and interlock prevent access during operation, ensuring safety throughout the testing process.Q: What types and sizes of pipes can be tested with this machine?

A: The tester accommodates plastic pipes with diameters from 32 mm up to 315 mm and lengths up to 500 mm. It is suitable for various materials, including PVC, PE, and PP, using specific hammers (D90, D250) in accordance with pipe size and applicable standards.Q: When should impact testing be performed on plastic pipes?

A: Impact resistance testing is recommended during quality control checks for new production batches, product certification, and research, or after storage and transport to ensure the pipes meet durability requirements specified in ISO 3127, IS 4984, and ASTM D2444.Q: Where is the ideal location for using this machine?

A: Designed for laboratory and industrial environments, this floor-standing tester fits into spaces approximately 900 mm by 800 mm. Its robust build and corrosion-resistant finish make it suitable for use by manufacturers, quality control labs, and research facilities.Q: What is the testing process using this impact tester?

A: The operator mounts the pipe on the adjustable V-block, sets test parameters via the touch panel, and safely initiates the drop hammer. The PLC system controls the release, and impact energy is displayed digitally. Results can be manually logged or exported electronically via RS232/USB.Q: How does the machine ensure accuracy and data reliability?

A: The equipment measures impact energy with a standard accuracy of 0.1 J and a resolution of 0.01 J. Digital LCD and optional electronic data logging provide reliable, traceable results, while the safety and interlock features maintain consistent testing conditions.Q: What are the main benefits of using this impact tester?

A: This machine offers rapid, automated, and safe impact resistance evaluation for quality compliance. Its versatility, adherence to international standards, and digital operation enhance efficiency and confidence in test outcomes for both manufacturers and laboratories.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+