HT-5169T-N High Accuracy Needle Flame Test Machine for Insulating Materials

Product Details:

- Usage Hospital & Laboratory

- Hardness Yes

- Material MS

- Voltage 110-215 Volt (v)

- Power Supply Manual

- Dimension (L*W*H) 1000 650 1300 Millimeter (mm)

- Click to view more

HT-5169T-N High Accuracy Needle Flame Test Machine for Insulating Materials Price And Quantity

- 1 Set

- 999.00 - 999.00 USD ($)/Set

- 1305.0 USD ($)/Set

HT-5169T-N High Accuracy Needle Flame Test Machine for Insulating Materials Product Specifications

- 1000 650 1300 Millimeter (mm)

- Yes

- Manual

- 110-215 Volt (v)

- Hospital & Laboratory

- MS

HT-5169T-N High Accuracy Needle Flame Test Machine for Insulating Materials Trade Information

- shenzhen

- Paypal, Telegraphic Transfer (T/T), Western Union

- 300 Set Per Month

- 7 Days

- standard exporting wooden package

- All India

- ISO9001:2015

Product Description

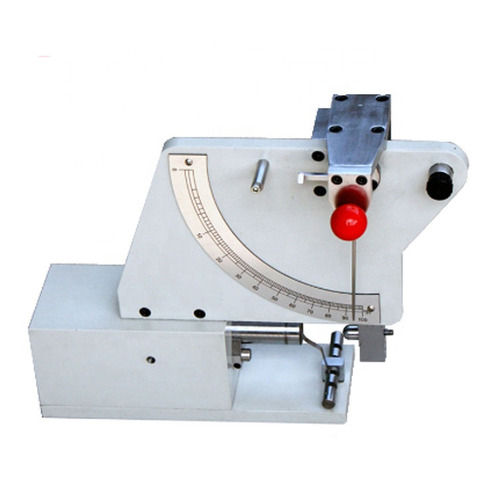

HT-5169T-N Needle Flame Tester / Needle Flame Test Machine / Instrument / Apparatus / Equipment / Device / Procedure

Application:

The needle flame tester uses a needle-shaped burner of a specified size (0.9mm), with a specific gas (butane or propane), and directionalally ignites the sample at an angle of 45o, depending on whether the test piece and the ignition bedding layer are ignition and holding time and length of combustion to assess the risk of fire from small flames inside the equipment due to fault conditions.

Needle flame tester is suitable for lighting, low-voltage electrical appliances, household appliances, machine tools, electrical machinery, power tools, electronic instruments, electrical instruments, information technology equipment, electrical affairs equipment, electrical connectors, accessories and other electrical and electronic equipment and components, also suitable for insulating materials, engineering plastics or other solid combustible materials industries.

Standards:

IEC 60695-2-2: 1991 (Second Edition), Amendment No. 1 of IEC 60695-2-2 (1994-03), IEC60695 -11-5, GB/T 5169.5-2008, GB4706.1-2005 The simulated test project specified by the standard.

Specification:

1.Needle burner: inner hole 0.5mm + 0.1mm, outer diameter 0.9mm, length 35mm, stainless steel

2.Burner angle: tilt 45o (test) or vertical (when adjusting the flame height)

3.Burning time: 0-999.9s + 0.1s adjustable (usually 30s)

4.Holding time: 0-999.9s + 0.1s, automatic recording, manual suspension

5.Flame height: 12mm + 1mm (with height measuring instruments)

6.The gas body: 95% butane gas (can use bottled lighter gas)

7.Temperature test range: 0-1000oC

8.Flame temperature requirements: from 100oC +2oC to 700oC + 3oC time within 23.5 seconds + 1 second

9.Temperature thermocouple: 0.5mm imported armored (K type) thermocouple

10.Needle flame burning tester test background: black background

11.Test process: automatic control of test procedures, independent ventilation

12.Reference standard: IEC60695 -11-5, GB/T5169.5-2008, GB4706.1-2005

13.The studio volume: 0.5 cubic (can be customized according to customer requirements 0.75 cubic or 1 cubic)

14.The outer dimensions of the equipment: 1000mm wide 650mm deep 1300mm high

High Precision Flame Testing for Various Materials

The HT-5169T-N Needle Flame Test Machine enables accurate simulation of fire conditions on insulating materials, ensuring compliance with international safety standards. Its sophisticated manual controls and high hardness build allow reliable and repeatable testing. This makes it essential for institutions demanding strict material safety evaluations in laboratory or hospital environments.

Versatile Voltage Compatibility and Manual Operation

Equipped for 110-215V operation, the HT-5169T-N adapts seamlessly to numerous electrical systems worldwide. The manual power supply provides the user with comprehensive oversight during test cycles, reducing risk of automation errors and increasing experimental precision.

FAQ's of HT-5169T-N High Accuracy Needle Flame Test Machine for Insulating Materials:

Q: How is the HT-5169T-N Needle Flame Test Machine operated?

A: The HT-5169T-N operates manually, allowing users to have direct control over test procedures. This ensures precise flame application and accurate simulation of fire scenarios on test specimens.Q: What materials can be tested with this machine?

A: This device is designed for testing the fire resistance of insulating materials, and can accommodate various sample types commonly used in industrial, laboratory, and hospital settings.Q: When should the HT-5169T-N be used?

A: Use the HT-5169T-N whenever there is a need to assess the flammability of insulating materials, especially during product development, quality control, or compliance with safety standards.Q: Where is this test machine commonly utilized?

A: It is frequently utilized in laboratories, research facilities, and hospitals, particularly in areas that require rigorous fire resistance testing of materials for safety assurance.Q: What is the process for conducting a needle flame test with this equipment?

A: The process involves placing the material specimen inside the machine, manually applying the needle flame to the required area, and observing the specimen's reaction according to standardized test protocols.Q: How does the HT-5169T-N benefit users in industrial or laboratory environments?

A: Its high accuracy, robust construction, and manual operation enhance testing reliability and repeatability, assisting organizations in ensuring their materials meet essential safety benchmarks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+