Welcome to Our Company

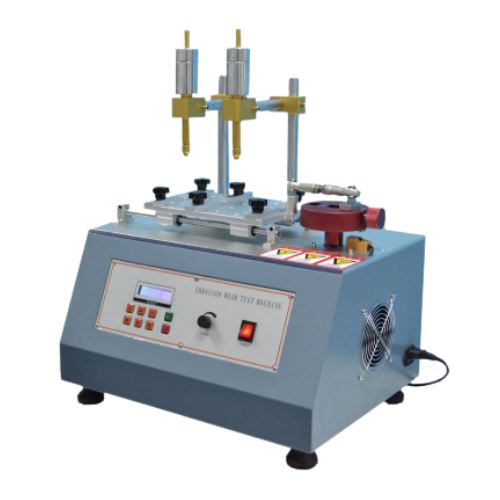

Ethanol Eraser Pencil Abrasion Tester

999.00 - 3599.00 INR

Product Details:

- Humidity 20% - 80% RH

- Mounting Type Benchtop

- Hardness Eraser shore hardness conform to standards

- Gas Pressure 0.5 MPa - 0.7 MPa

- Automation Grade Semi-automatic

- Application Pencil abrasion resistance test for coatings, inks, and printed surfaces

- Accuracy 1 cycle

- Click to view more

X

Ethanol Eraser Pencil Abrasion Tester Price And Quantity

- 1 Set

- 999.00 - 3599.00 INR

- 450 mm 350 mm 400 mm

- Clamp with adjustable tension

- Powder coated steel body

- 65 dB

- Transparent cover, emergency stop button

- Manual via slide mechanism

- Adjustable

- Standard eraser, pencil holder, air regulator

Ethanol Eraser Pencil Abrasion Tester Product Specifications

- Benchtop

- Eraser shore hardness conform to standards

- 0.5 MPa - 0.7 MPa

- Coating, paint, and print abrasion tests

- Semi-automatic

- 20% - 80% RH

- 50/60 Hz

- AC 220V, 50/60 Hz

- 0 99999 cycles

- 60 mm (standard), adjustable

- 1 at a time

- 15C - 35C

- Approx. 40 kg

- Pencil abrasion resistance test for coatings, inks, and printed surfaces

- 1 cycle

- LCD digital display

- 5 mm - 30 mm adjustable

- Eraser load 500g

- <1 second

- 43 cycles/min

- 220V AC

- Ethanol Eraser Pencil Abrasion Tester

- Max 120 mm 50 mm

- Standard power input

- Programmable cycles, automatic stop, adjustable load, safety shield

- 6 mm air tube

- 1 99999 cycles

- 1 cycle

- 350 mm

- Digital microcontroller based

- 450 mm 350 mm 400 mm

- Clamp with adjustable tension

- Powder coated steel body

- 65 dB

- Transparent cover, emergency stop button

- Manual via slide mechanism

- Adjustable

- Standard eraser, pencil holder, air regulator

Ethanol Eraser Pencil Abrasion Tester Trade Information

- shenzhen

- 300 Set Per Month

- 7 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

Ethanol Eraser Pencil Abrasion Tester

Application

rubbing resistance testing for all kinds of surface of coating products. Adopt high precision transmission parts made in Japan.stable operation and low noise. Standard configuration:hardness scratch testing clamp;eraser testing clamp, ethanol testing clamp.

Parameter

- Testing loading:70-950g

- Testing time:0-99999999 times

- Maximum table loading capacity:5kg

- Moveable range:2-50mm(or discussion)

- Testing speed:15-80 times per minute

- Loading weights:10,20,50,100,200,500g

- Motor power:40W

- External dimension:500*450*540mm

- Weight:45kg

Designed for Accurate and Reproducible Testing

This abrasion tester delivers reliable measurements through its digital control and adjustable features. The machine enables precise calibration of eraser load, test width, and stroke length. Its programmable cycle counter allows for extended, repeatable testing routines, making it a valuable tool for quality control and research in coatings, paints, and print durability assessments.

User-Friendly and Safe Operation

Safety and usability are fundamental. The tester is equipped with a transparent shield to protect users and an emergency stop button for instant intervention. Its intuitive LCD digital display provides real-time data on cycles and enables quick setup via its microcontroller interface. The powder-coated steel body and moderate noise level ensure comfortable, long-term use in laboratory environments.

Versatile Applications and Robust Construction

Capable of testing specimens up to 120 50 mm and handling an eraser load of 500g, this tester accommodates various product types. The adjustable holders and air regulator make it suitable for diversified tasks. Its robust construction and semi-automatic design provide durability and flexibility for manufacturers, suppliers, and exporters seeking dependable abrasion resistance data.

FAQs of Ethanol Eraser Pencil Abrasion Tester:

Q: How is the specimen fixed in the Ethanol Eraser Pencil Abrasion Tester?

A: The tester employs a clamp mechanism with adjustable tension to securely hold specimens up to 120 mm 50 mm in size. This allows users to easily load, adjust, and stabilize various surface materials for consistent abrasion tests.Q: What types of materials can be tested with this abrasion tester?

A: It is suitable for evaluating abrasion resistance on coatings, inks, and printed surfaces. Commonly used in the paint, printing, and coating industries, the tester supports research, quality control, and manufacturing environments.Q: What is the testing process with this device?

A: To perform a test, the specimen is clamped, test parameters (like width, stroke, and cycles) are set on the LCD display, and the adjustable eraser or pencil holder is positioned. Testing is initiated via the digital controller, and cycles proceed automatically up to 43 per minute, concluding with an automatic stop.Q: Where can this device be used?

A: This benchtop tester is designed for laboratory or quality assurance environments in manufacturing plants, research facilities, and testing institutions engaged in coatings, paints, and printed product evaluations.Q: When should you use the emergency stop feature?

A: The emergency stop button should be pressed whenever there is an operational anomaly, safety hazard, or need for immediate interruption of the test. It instantly halts all movement to ensure operator safety.Q: What are the key benefits of using this abrasion tester?

A: Key benefits include high testing accuracy (1 cycle), versatility in test parameters, low noise operation (65 dB), robust safety features, digital programmability, and compliance with standard eraser hardness requirements. This ensures dependable and consistent test outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email