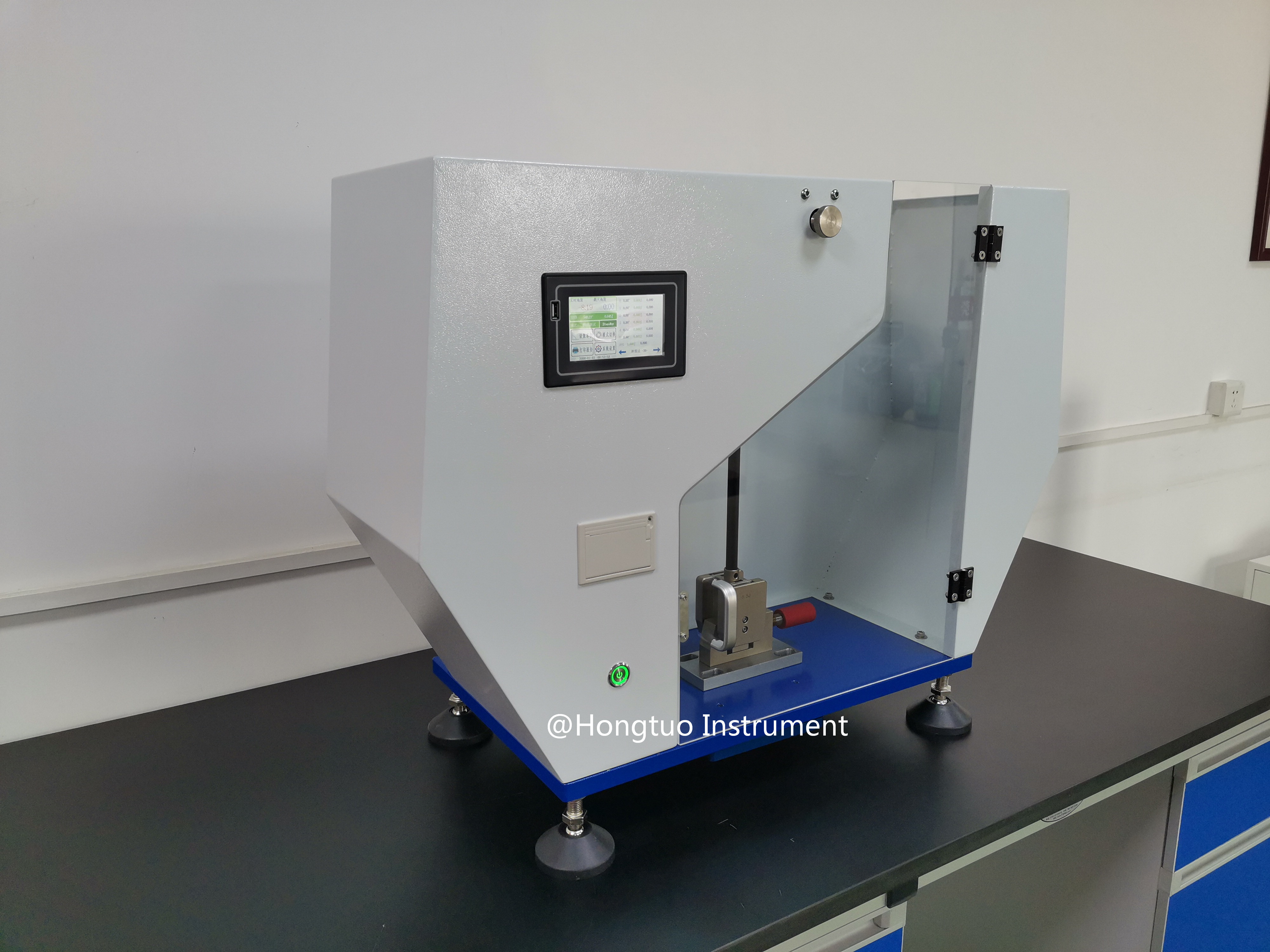

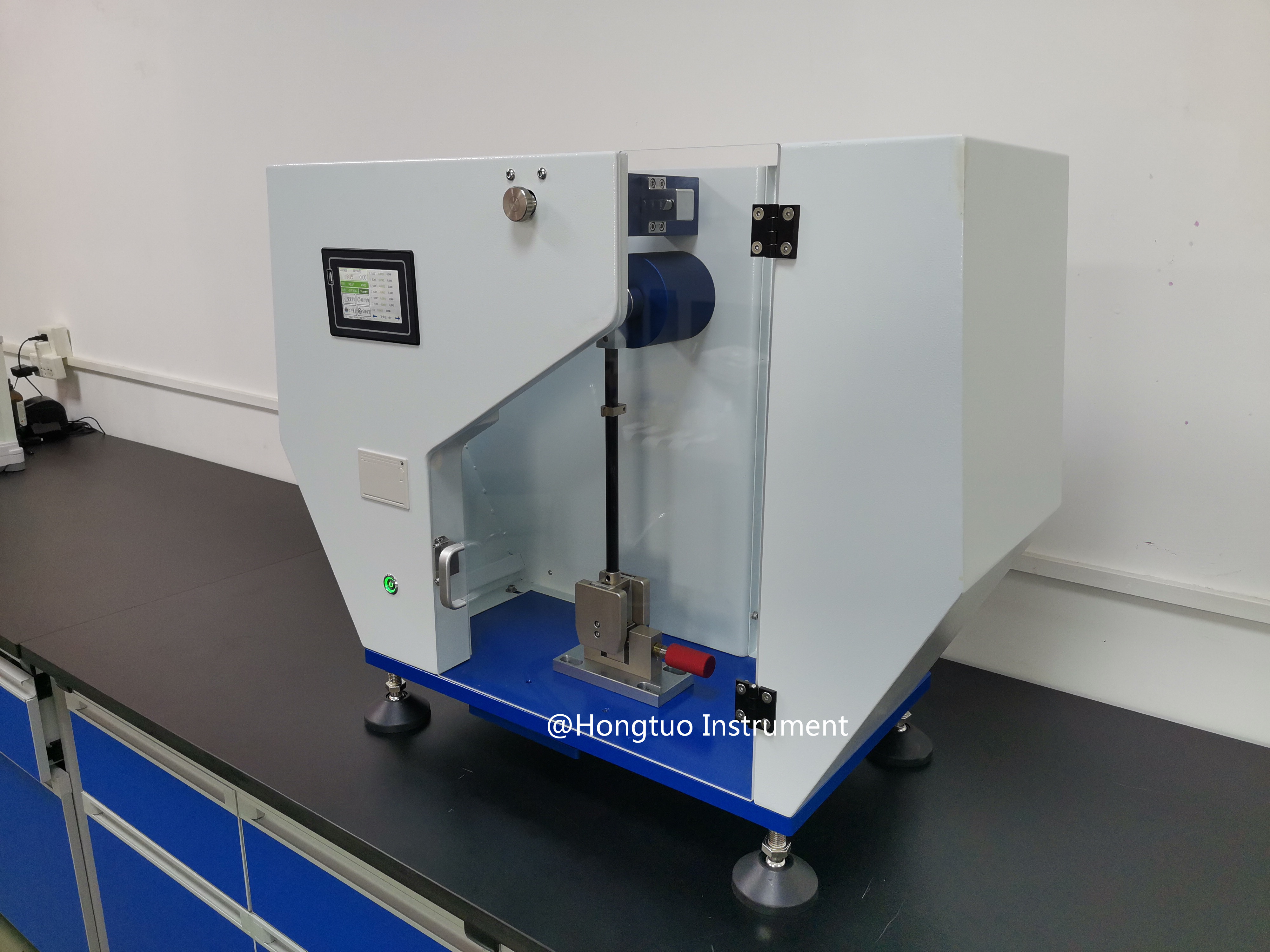

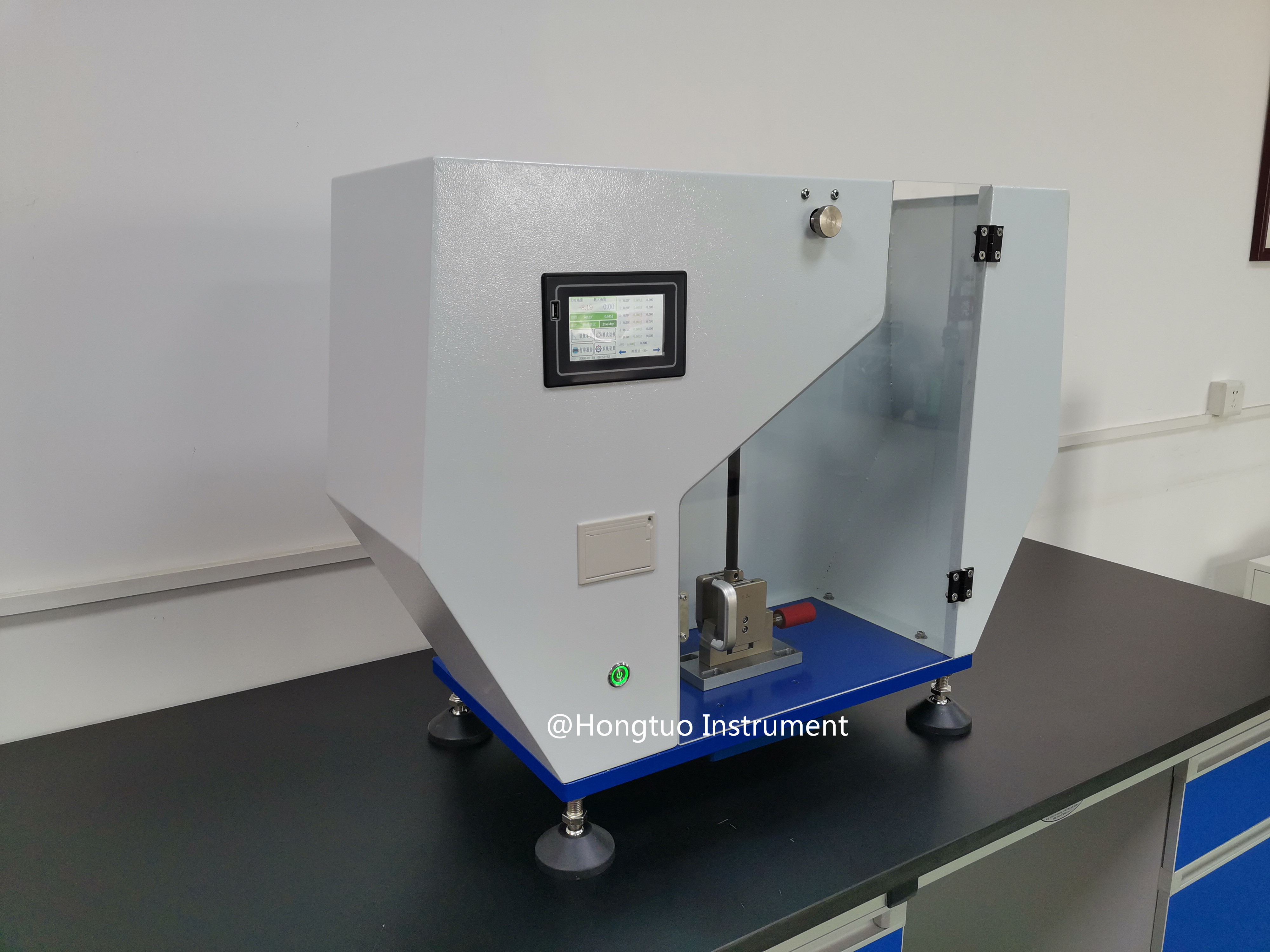

Professional Izod Pendulum Impact Test Machine

Product Details:

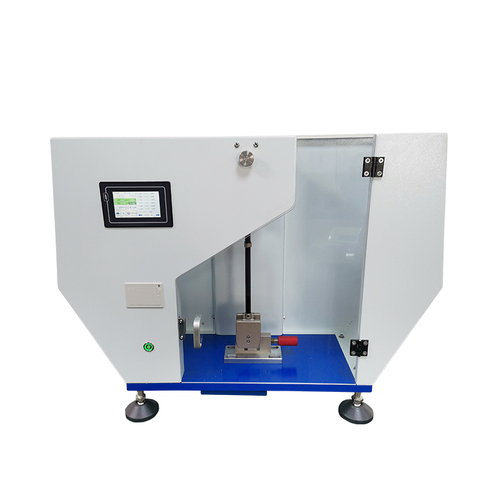

- Equipment Type Pendulum Impact Test Machine

- Accuracy 0.1 Joule

- Power Supply 230V AC, 50Hz

- Automation Grade Manual

- Application Measuring impact resistance/strength of materials such as plastics, metals, and composite specimens

- Resolution 0.01 Joule

- Max Height Approx. 550 mm

- Click to view more

Professional Izod Pendulum Impact Test Machine Price And Quantity

- 899.00 - 2299.00 USD ($)

- 1 Set

Professional Izod Pendulum Impact Test Machine Product Specifications

- Up to 85% RH non-condensing

- 10 mm nominal

- 50 Hz

- 1 per test

- Up to 25 Joules

- Direct/Digital

- Table Top

- Manual Release, Digital Reading

- Laboratory and industrial impact testing

- Rugged construction, ergonomic handle, high-precision digital indication, replaceable striking edge

- 230V AC

- Standard IZOD stroke (maximum angle to base)

- Immediate (real-time digital readout)

- Machine body Hardened steel

- 0 25 Joules

- 75 mm 10 mm 10 mm

- 0.01 Joule

- Measuring impact resistance/strength of materials such as plastics, metals, and composite specimens

- Manual

- Approx. 550 mm

- Digital Display

- 10C to 35C Operating Range

- 0~25 J (Joules)

- Approx. 100 kg

- 3.5 m/s

- Pendulum Impact Test Machine

- 230V AC, 50Hz

- 0.1 Joule

Professional Izod Pendulum Impact Test Machine Trade Information

- shenzhen

- 300 Set Per Month

- 7 Days

- Standard export wooden package

- All India

- CE, FCC

Product Description

Application: scientific research institutes, universities and non-metallic material manufacturers as the common quality test equipment.

Performance standards

GB/T1843-2008 Rigid Plastic Izod Impact Test Method

JB/T8761-1998 Plastics Izod Impact Testing Machine

ASTM D256-2010 Test Methods for Measuring the Impact Strength of the Plastic IZOD Pendulum

Product Features

B. Chinas first carbon fiber lever (It has been patented); it succeeds in doing experiments without shaking involving the impact direction, improving the rigidity of materials, and concentrating impacting strength on the centroid of the pendulum, and using life increases.

C. Imported high-resolution digital encoders, higher and more stable angle measurement accuracy;

D. Aerodynamic impact hammer and FAG Bearings greatly reduce mechanical friction losses

E.Automatic calculation of the final result, 20 sets of the test data can be stored and averaged;

F. Optional interface of Chinese and English; units ( J / m, KJ / m2, kg-cm / cm, ft-ib / in )can be customized according to customers requirements.

G. Built-in mini printer to print the test data.

H.Equipped with a brake device, which greatly improves safety and test efficiency.

Technical Specifications

Displaying method: LCD in English

Angle sensor: Omron encoder,accuracy 0.01

Impact speed: 3.5m/s

Pendulum energy: 11J,22J

Pendulum angle: 150

Distance from the center of pendulum to striking edge: 335mm

Horizontal distance from striking edge to jaws: 22mm

Weight: 85kg

Power voltage: 110-220V 50/60Hz

Advanced Safety and Durability

This machine incorporates multiple safety features, including an interlock shield and base anchoring, to protect users during operation. Its rugged frame, made from powder-coated, hardened steel, ensures longevity and minimal maintenance, even in demanding laboratory and industrial settings.

Precision Measurement Technology

Automatic correction for energy losses, combined with digital real-time readout, delivers highly accurate impact resistance results. The integrated bubble level and replaceable striking edge further enhance the measurement precision. The equipment comes with a standard calibration certificate, ensuring reliability.

Versatile Application and Easy Setup

Designed for testing specimens of plastics, metals, and composites, this tabletop machine is easy to install using the integrated level indicator. Its ergonomic handle and straightforward manual controls make it suitable for both laboratory and industrial usage, accommodating a wide range of materials and test environments.

FAQs of Professional Izod Pendulum Impact Test Machine:

Q: How does the Izod Pendulum Impact Test Machine operate?

A: The machine uses a 2.75 kg pendulum, which is released either electro-magnetically or manually. The pendulum strikes the specimen, and the impact energy absorbed is measured automatically with correction for friction and windage losses. Results are displayed instantly on the digital readout.Q: What materials can be tested with this machine?

A: This impact test machine is suitable for evaluating the impact resistance of plastics, metals, and composite specimens. It is widely used in both laboratory and industrial environments for material quality assessments.Q: When should I calibrate the impact test machine?

A: Calibration is recommended whenever the accuracy of results is critical or after significant maintenance. The machine comes with a standard calibration certificate to ensure reliable performance from the outset.Q: Where should the machine be installed for optimal performance?

A: Install the machine on a stable tabletop in a laboratory or industrial environment, maintaining an operating temperature range of 10C to 35C and humidity up to 85% RH non-condensing. The integrated bubble level provides precise horizontal setup.Q: What is the process for conducting an impact test?

A: Place a properly sized specimen (75 mm 10 mm 10 mm) in the holder, set the desired release mode, and initiate the pendulum. The machine automatically measures the absorbed energy, corrects for losses, and displays the result digitally.Q: How does the automatic energy loss correction benefit the test results?

A: Automatic compensation for friction and windage ensures that the measured impact energy accurately reflects the materials resistance, improving the repeatability and reliability of your results.Q: What are the main advantages of using this test machine?

A: Key benefits include high measurement precision (resolution up to 0.01 Joule), rugged construction for durability, user-friendly digital interface, enhanced safety features, and quick setup, making it an essential tool for material impact resistance testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+